Symach is installing a new FixLine system in Australia

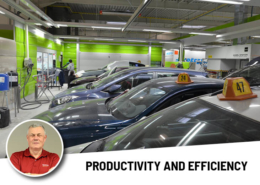

Peter Wilkinson & Co. collision repair shop, authorized for Mercedes Benz, Genesis, Lexus, BMW and Mini, located in Perth, WA, is an ISO 9002 certified Company established in 1959. With Symach Kombiking Fixline system, they will be able to do up to 16 job cycles a day.

This FixLine system is made of a Dryking spray booth with PowerLed lighting system, and the innovative Kombiking (patented) drying booth, completely covered internally in stainless steel.

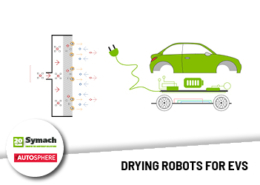

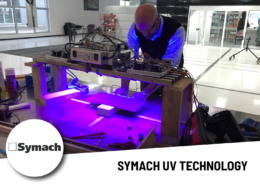

This innovative drying booth works with IR technology, evenly reflected by the internal stainless steel walls to any surface of the vehicle or the parts in the booth. The IR technology dries solidifying the paint particles by means of electromagnetic waves generated by a chemical reaction; that allows to keep a low temperature in the booth, thus not damaging the batteries of electric vehicles, nor the sensitive electronics systems of modern cars.

The two booths work in combination, both managed by a PLC (Program Logic Control) featuring a touch screen, sending all work data to the cloud storage in the technical platform REMO, designed and implemented by Symach.

This most powerful Kombiking FixLine system includes a preparation bay equipped with the Paint Window Extraction, a vertical air extraction system, and a FlyDry Hybrid drying robot. Thanks to the perfect enclosure of its electric curtains, this preparation bay can therefore work also as a paint and drying area for classic and UV primer application.

The accessories present along the line include some Columns to host a few Multibox for air and electricity retractable pipes, and a Vacuum Sanding System for 2 operators. The PowerLed lighting systems covers all working bays along the FixLine. A large and well equipped Paint Mixing Room and the CarMover system complete the description of this efficient and productive Kombiking FixLine.

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl