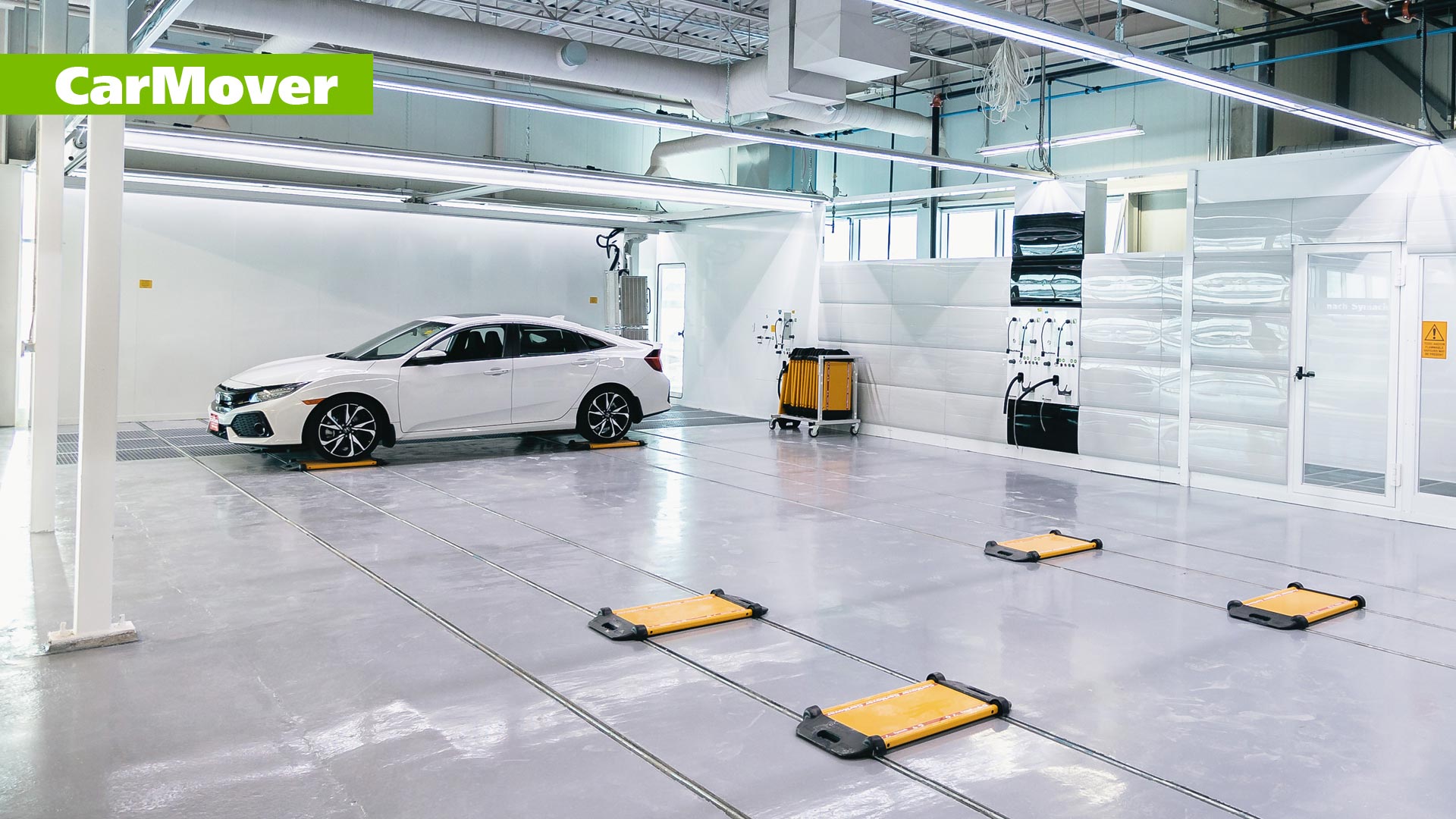

Side-loading system to move vehicles

The CarMover side-loading system is composed of four plates and works on rails using one plate for every wheel of the vehicle. It is easy, fast, effortless and is designed to be used by just one technician.

TECHNICAL FEATURES OF THE SIDE LOADING SYSTEM

Each plate weighs only 8 kg or 17.6 pounds. By design, it is easy for the technician to move the vehicle from the end of the conveyor line to the starting point. Each plate’s load capacity is 700 kg or 1,543 pounds.

The plate is produced with a special aluminum alloy and geometric structure, which guarantees no bending. The plastic connectors, on each side of the plate, permit the vehicle wheels to go up to the plate effortlessly and without any slipping problems.

This side-loading system allows one technician to move a vehicle along the paint line by pushing it with an effort of only 12 Kg or 26 lb. The design uses special wheels and a rail system where the point of contact between them is very thin, reducing the friction to a minimum and permitting a technician to move the vehicle using little effort. This is a fundamental bodyshop equipment to help improve productivity.

The CarMover works with two different types of rails, having the same performance. One is inside the floor level and the other one is above floor level.

The number of rail positions is five per bay in Europe and six in North America. This allows the CarMover side-load system to accommodate every model and size of vehicle.

Symach uses the CarMover side-loading system in every FixLine layout.

MOVING PERFORMANCE

The CarMover allows one technician to move a vehicle using only 12 kg or 26 lb of effort.

CONFIGURATION

The CarMover uses:

– four plates for every bay,

– the rail’s position per bay are five in Europe and six in North America, due to the different lengths of cars,

– two models of rails: Rail In is inside the floor lever or Rail Out is outside the floor level

– trolley for plates.

PLATE FRAME

The plate is extruded with a special aluminum alloy that permits a deflection of only 1 mm or 0.04 “, under vehicle load, but always returns to the original shape with no permanent deformation.

Every plate has a no-collision system to avoid the technician pushing the car too far and damaging another one.

PLASTIC CONNECTORS

There are two connectors for every plate, which are constructed from an elastic plastic mix with a specific geometry. This allows them to flex toward the floor to facilitate the car wheel moving onto the plate and then returning to its original position.

TEMPERED STEEL WHEEL

The CarMover wheels are made with bearings and with a self-centering system on the rails.

RAIL OUT

The rails over the floor level are constructed from a metal section with a specific design and are easily installed on the floor and secured with anchor bolts.

The rails protrude over the floor level by 2 cm or 0.78 “ and have ramps on both sides to help wheels and pedestrians pass over them.

RAIL IN

The rails inside the floor level are constructed from a metal section with a specific design and are installed inside the floor level. They can also be installed inside the grid of the spray booth and the preparation bay.