What sets our patented “Drytronic” gas catalytic infrared technology apart from competitors in the market?

Drytronic’s patented technology utilizes an exothermic catalytic chemical reaction that combines hydrogen and oxygen using natural gas or LPG. This process generates a wide range of infrared wavelengths, spanning from short to long waves, encompassing an exceptionally broad spectrum.

The targeted and precise range of electromagnetic waves the DryTronic generators emits, enables the release of over 85% of the energy stored within the paint molecules.

Our patented Wave Length Control System (WLC) enables efficient management of the different wavelengths, tailored to dry any specific type and brand of paint.

This allows Symach equipment to quickly and efficiently dry any type of bodyfiller with just one pass, as well as top layers. Penetrating directly to the surface of the materials, short waves heats the coating, rapidly curing it from inside out, while medium-long waves cure the top layers at the same time.

DETAILS OF THE CHEMICAL REACTION

The occurrence of the chemical reaction is facilitated by the catalyst present within the lamp, which disrupts the chemical bonds within the gas molecules, effectively separating hydrogen from carbon.

Upon exiting the lamp, the hydrogen undergoes oxidation when it encounters oxygen, resulting in the generation of flameless energy. As the process does not involve combustion, the carbon is released into the atmosphere in the form of carbon dioxide.

DRYTRONIC TECHNOLOGY IS EFFICIENT

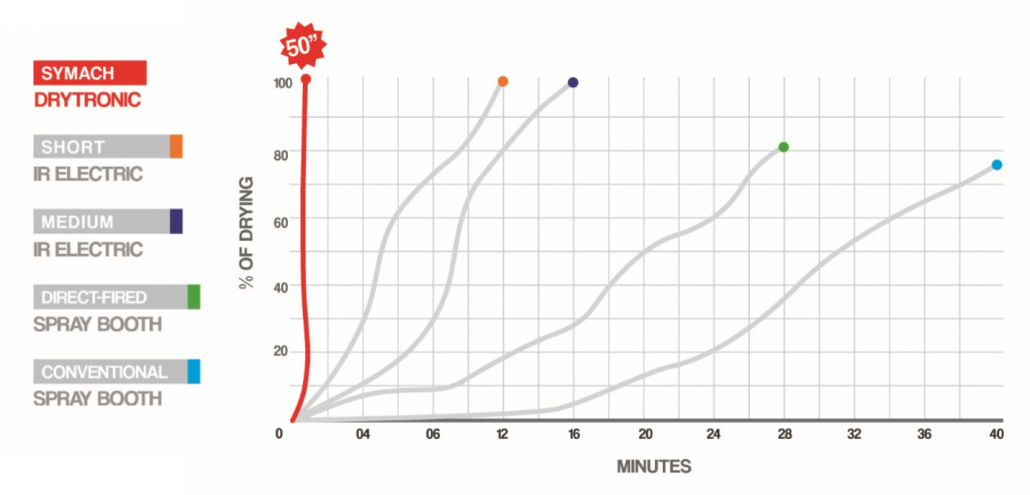

The Drytronic wave spectrum penetrates directly into the paint molecule, instantly drying it: for example, it takes as little as 50 seconds to dry clear lacquer.

The Drytronic unit offers versatile drying capabilities of various paints, materials and thicknesses, with almost no differences in terms of drying time and quality. The catalytic lamp emits radiation within a cone of fifty degrees, effectively enlarging the exposure area and yielding two key advantages.

Firstly, it enables a gradual and even rise in paint temperature, which is closely monitored by multiple sensors and temperature control devices.

Secondly, it facilitates precise measurement of the power you are bringing to a panel when curing, to prevent issues such as solvent popping or skinning, ensuring optimal drying even on complex angles or undercut curves.

By utilizing DryTronic technology, drying times are significantly reduced during both preparation and paint phases, leading to increased productivity in the body shop. Consequently, this not only results in reduced overall energy consumption but also contributes to lowering the carbon footprint of the autobody shop.

You can obtain faster curing and better finishes with DryTronic technology.

THE SAFEST WAY TO QUICKLY CURE ELECTRIC VEHICLES

Electric vehicles require lower curing temperatures compared to vehicles with internal combustion engines, making it challenging to cure them using a standard paint booth cure cycle. However, the ideal solution for this issue is the implementation of DryTronic infrared technology.

Symach’s patented Drytronic infrared drying technology is specifically designed to be EV-Ready. It focuses its energy directly on the painted surface, without raising interior or undercar/underhood temperatures. This ensures that no excessive heat is transferred to the electric batteries or the vehicle’s electronics, providing a safe and efficient drying process.

Furthermore, the energy-efficient nature of the Drytronic system contributes to reduced operating costs while promoting environmental sustainability.

Given these advantages, Drytronic technology is highly recommended for drying body filler and paint on electric vehicles, ensuring optimal results without compromising the vehicle’s sensitive components.

DRYTRONIC TECHNOLOGY IS SAFE

The Drytronic technology is entirely safe for human health, with absolutely no side effects resulting even from prolonged exposure. Furthermore, there are no risks posed to the eyes, since the radiation is in a wave spectrum that is entirely invisible to the human eye itself.

Since the catalytic chemical reaction takes place in the total absence of flames, there is no risk of fire or explosion, even if the panel comes into contact with flammable liquids or gases. The Drytronic panel is therefore ATEX certified and approved for use in environments where explosive mixtures may be present, such as spraybooths.

Drytronic drying tech is available on several Symach bodyshop equipment along the FixLine, such as drying robots EasyDry and FlyDry, and in the KombiKing (patented) drying cabin.

FUTURE PROOF your bodyshop with Symach!