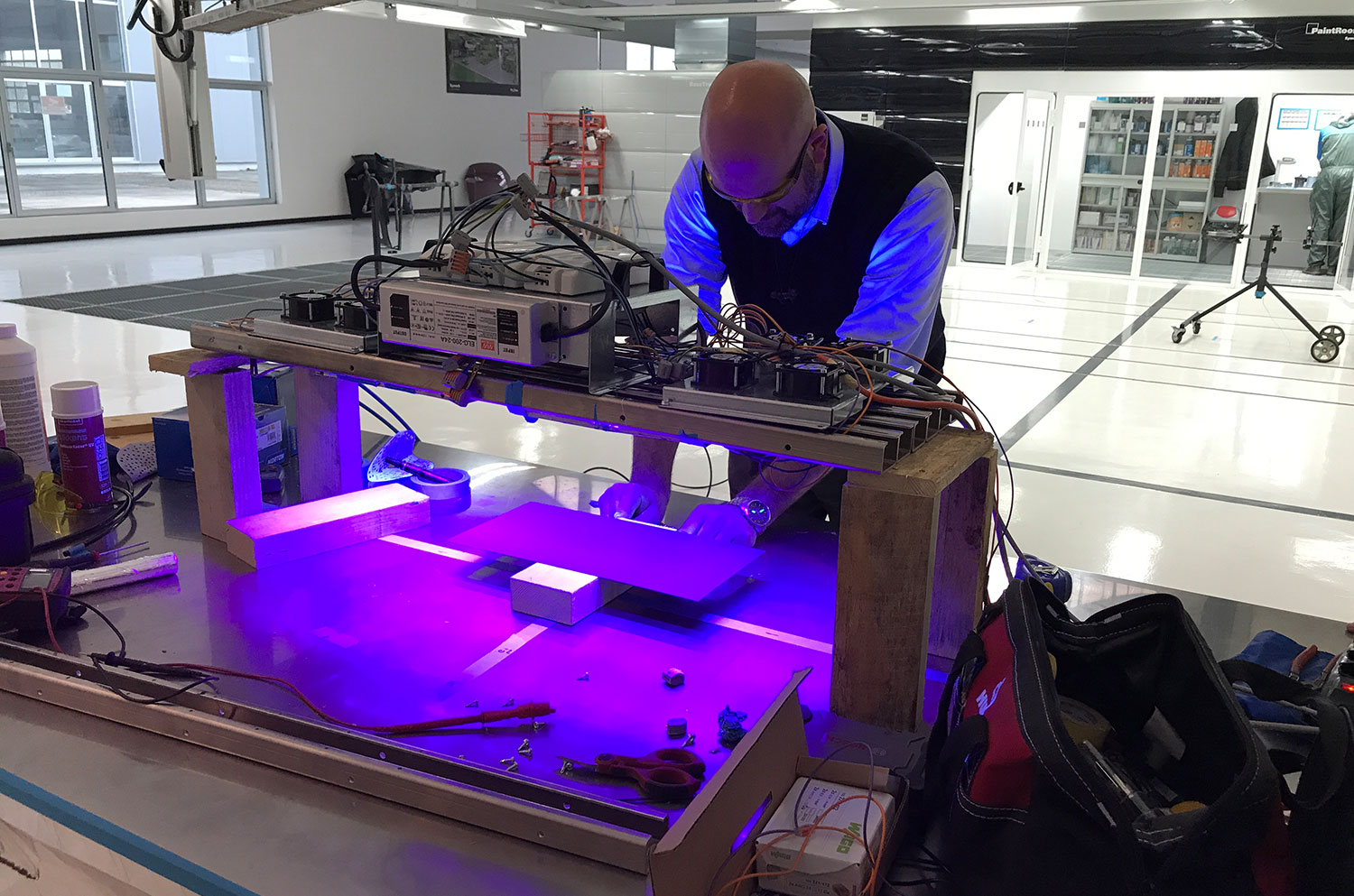

UVA-LEDtronic Technology

The LED-Tronic technology, developed by Symach’s R&D division, combines extensive research on UV coatings, LED selection, mechanical design, and performance optimization. Over 18 months of dedicated work resulted in outstanding performance, surpassing previous barriers and limitations that hindered the technology’s adoption.

TECHNICAL CHARACTERISTICS OF THE UVA-LEDTRONIC TECHNOLOGY

The LEDs used are of different wavelengths all in the UV-A segment. These are assembled along a line of reflectors studied and designed to achieve the fastest and most efficient drying result on the market. They are controlled by an electronic board with a temperature control device that close the electric power in the event of the device overheating due to prolonged and continuous use of it.

We install the LEDs on an aluminium support equipped with a heat sink, allowing prolonged use of the lamp also for drying several car panels in sequence.

DRYING TIMES OF THE UV PRODUCTS

For the most common UV products the exposure time is about 30/40 seconds, the exposure time is also proportional to the type and thickness of the sprayed product. However, it is enough to pass regularly on the sprayed product at a distance of 5 to 10 cm. (2 “ to 4”) for a few seconds to obtain perfect drying. To dry the UV coating product (body filler, primer, clear) refer to the instructions of your paint producer.

It is possible to use the UV lamp even between first and second coat, this will allow a greater speed of execution and a greater safety of drying in the case of paint application in excess of thickness.

The UV technology is installed on the portable UV coating drying lamps, the drying robot FlyDry, in the BaseTron preparation bay along the FixLine system.