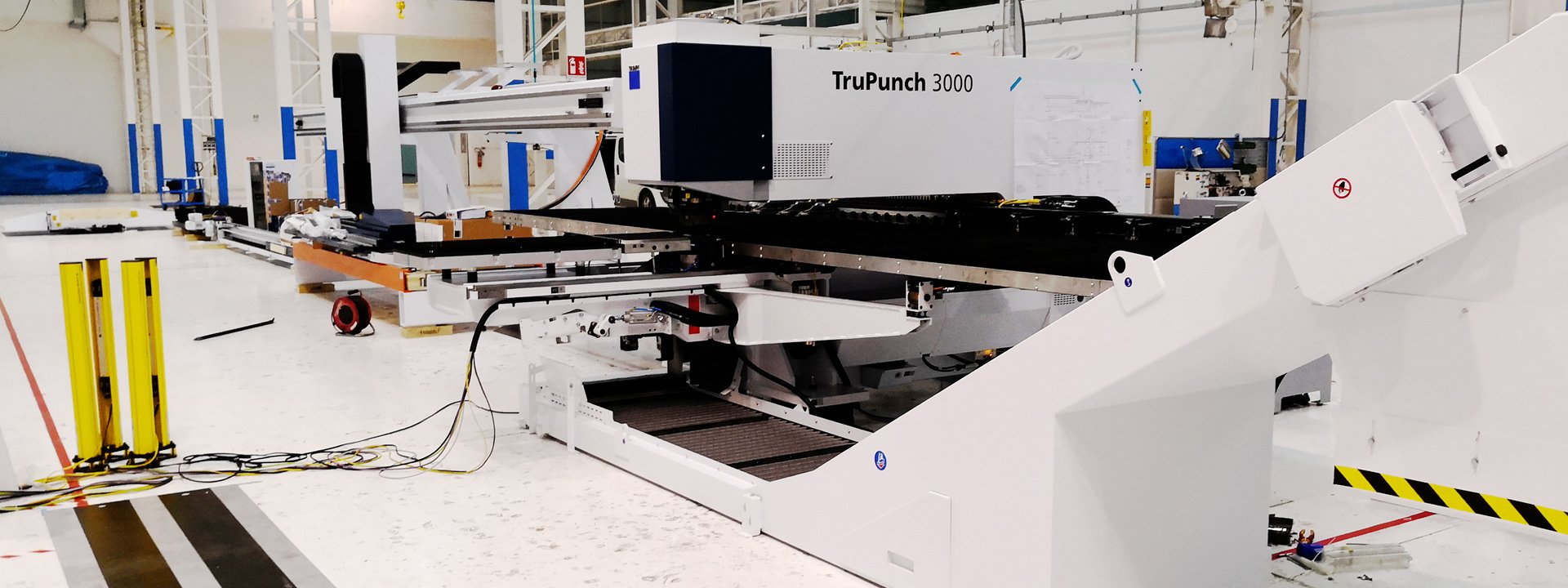

Symach’s R&D division

Production line

Since 2001, Symach has been at the forefront of producing innovative solutions for the collision repair industry

Everyday, small and large auto body shops, multiple shop owners and car dealers, rely on Symach’s equipment and innovative tools to boost productivity, efficiency, and maintain a safe and clean working environment.

For two decades, Symach has been a global advocate for bodyshops guiding them in transitioning from traditional repair processes to cutting-edge lean processes, leveraging state-of-the-art technology.

Symach’s product lineup include spraybooths, drying robot, UV lamps, LED shop lighting, and the groundbreaking FixLine innovation

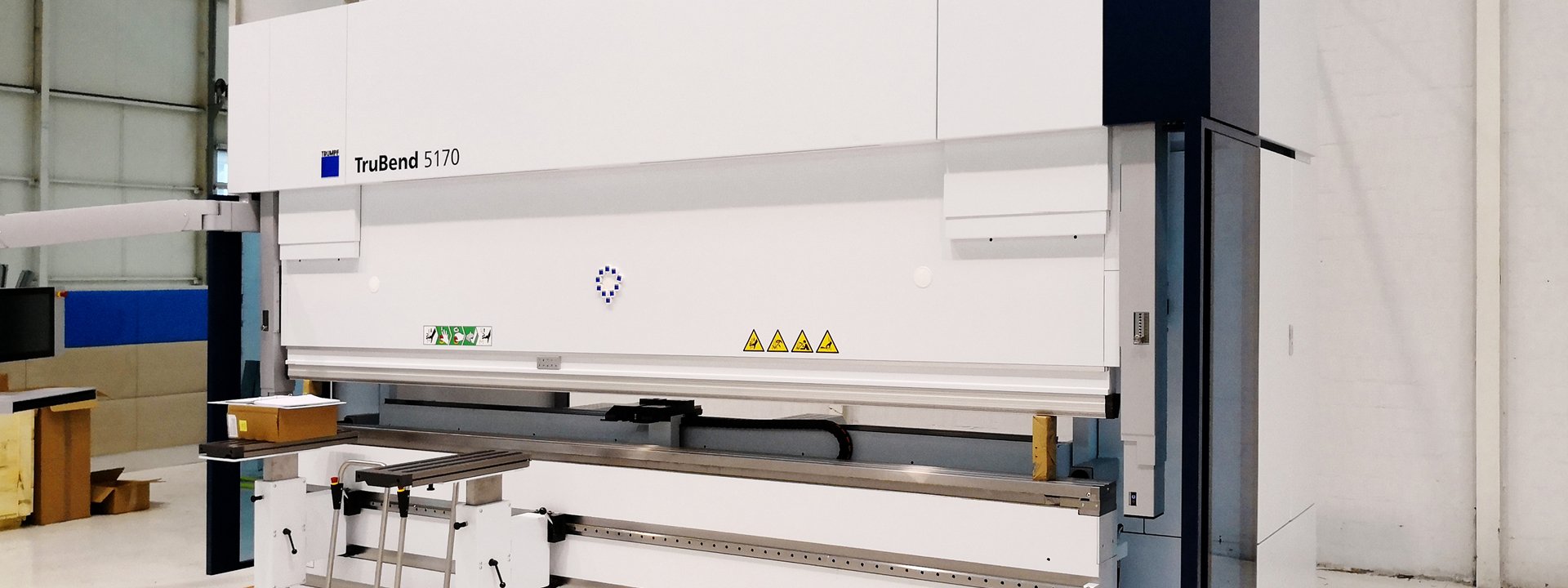

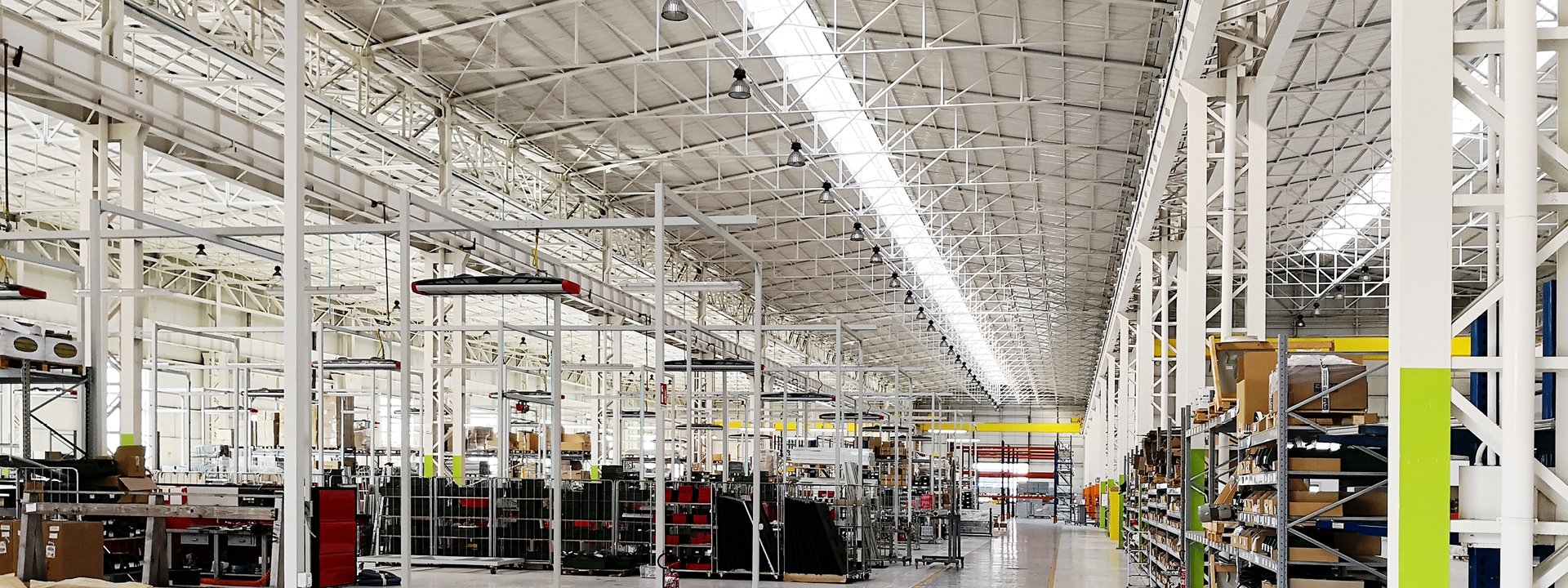

All these products are meticulously designed by Symach’s R&D engineers, utilizing top-quality components. Manufacturing takes place at Symach’s sprawling 15,000m2 (160,000 sq ft) headquarters in Bologna, Italy. Installation is performed by trained experts.

FixLine, a repair process implemented in a conveyor system, revolutionizes everyday repairs by significantly reducing the actual time a car spends inside the bodyshop, up to 40% or two days. Moreover, it reduces labor costs by an average of 3 to 4 hours per repair. Symach’s curing systems also play a crucial role in reducing energy consumption by up to 90%, thereby positively impacting the environment and minimizing the bodyshop’s carbon footprint.

Symach, founded in 2001 by Osvaldo Bergaglio in Bologna, Italy, initially began as a research project focused on developing a new technology for drying automotive paint. This endeavor led to the creation of Symach’s groundbreaking drying technology known as DryTronic.

DryTronic drying technology enables automotive paint to cure in less than one minute, revolutionizing the painting process. In 2002, Symach introduced its first robot for automotive body shops, named RoboDry, and also developed a rapid spraying and drying process called SPAP (Symach Paint Application Process), suitable for all brands and types of automotive paint.

Over the years, Symach has expanded its product range to offer a comprehensive lineup of equipment for automotive collision repair centers. With its complete solution for new body shops, Symach has been designing and installing cutting-edge facilities worldwide since 2010, employing the innovative Symach FixLine process. As of 2015, more than 2,600 robots and over 130 complete automotive body shops equipped with the Symach FixLine process have been sold across Europe, the Middle East, Australia, and North America.

In January 2016, Symach relocated to a larger factory occupying 15,000 square meters (161,500 square feet) in Calderara di Reno, Bologna, Italy, to accommodate its expanding operations.

One of Symach’s primary specialties lies in offering a revolutionary repair process to body shops known as FixLine. By implementing the FixLine repair process, shops can significantly reduce the overall throughput time to 1.5-2 days, while also experiencing a decrease of approximately 3-4 hours in labor costs per repair.

Assembly line

Warehouse Department

Today, Symach has established itself as a global organization dedicated to designing, producing and installing new body shops worldwide. With a dedicated international team of over 30 employees, Symach possesses the expertise and resources to guide body shops through the conversion process from traditional methods to the innovative FixLine process. As more than just an equipment manufacturer, Symach takes pride in being a comprehensive collision repair solution provider, offering extensive knowledge and understanding of the automotive collision repair process.

In addition, Symach operates in strict adherence to all legal requirements and industry standards, ensuring compliance with certifications that validate the company’s commitment to quality and safety.