Auto Body Repair and Paint Booth

The FixStation is an all-inclusive body shop solution that offers a contemporary and innovative approach to achieving high productivity and quick turnaround for one or two-panel repairs.

It is a versatile hybrid solution that combines the functionalities of a spraybooth and a workstation in a single location.

With this unique setup, a single technician with multiple skills can efficiently carry out an average of three to four repairs per day, without the need to move the vehicle. As a result, it enables a remarkable turnaround time of one repair every two to three hours.

Within the FixStation, technicians can efficiently remove and install parts, perform dent repair, apply body filler, spray primer, as well as apply and dry waterborne or solvent-based basecoat and clear coat. It provides all the necessary tools and facilities for a technician to complete these various tasks in a convenient and efficient manner.

CUSTOMIZE YOUR FIXSTATION

For a complete and efficient bodyshop setup, the FixStation can be equipped with several components. These include:

1. FlyDry Robot: the inclusion of a FlyDry robot, ensures efficient and effective drying of paint on repaired surfaces, enhancing productivity and reducing drying time.

2. Vacuum Sanding System: the integration of a Vacuum Sanding system helps capture and contain dust and debris generated during the sanding process, promoting a clean and safe working environment.

4. MultiBox with Plugs and Retractable Air and Electric: the inclusion of a MultiBox equipped with plugs and retractable air and electric connections allows for easy access to power and air supply, facilitating seamless operations and minimizing clutter.

DRYING PERFORMANCE

The FixStation uses the FlyDry robot to dry paint.

DRYING TIMES FOR CONVENTIONAL PAINTS

Bodyfiller 80/100 linear cm (32/39″) per minute

Primer 70/90 linear cm (27/35″) per minute

Waterborne 80/120 linear cm (32/47″) per minute

Clearcoat 60/90 linear cm (24/35″) per minute

DRYING TIMES FOR UV PAINTS

Bodyfiller and Primer 80/100 linear cm (32/39″) per minute

Clearcoat 60/90 linear cm (24/35″) per minute

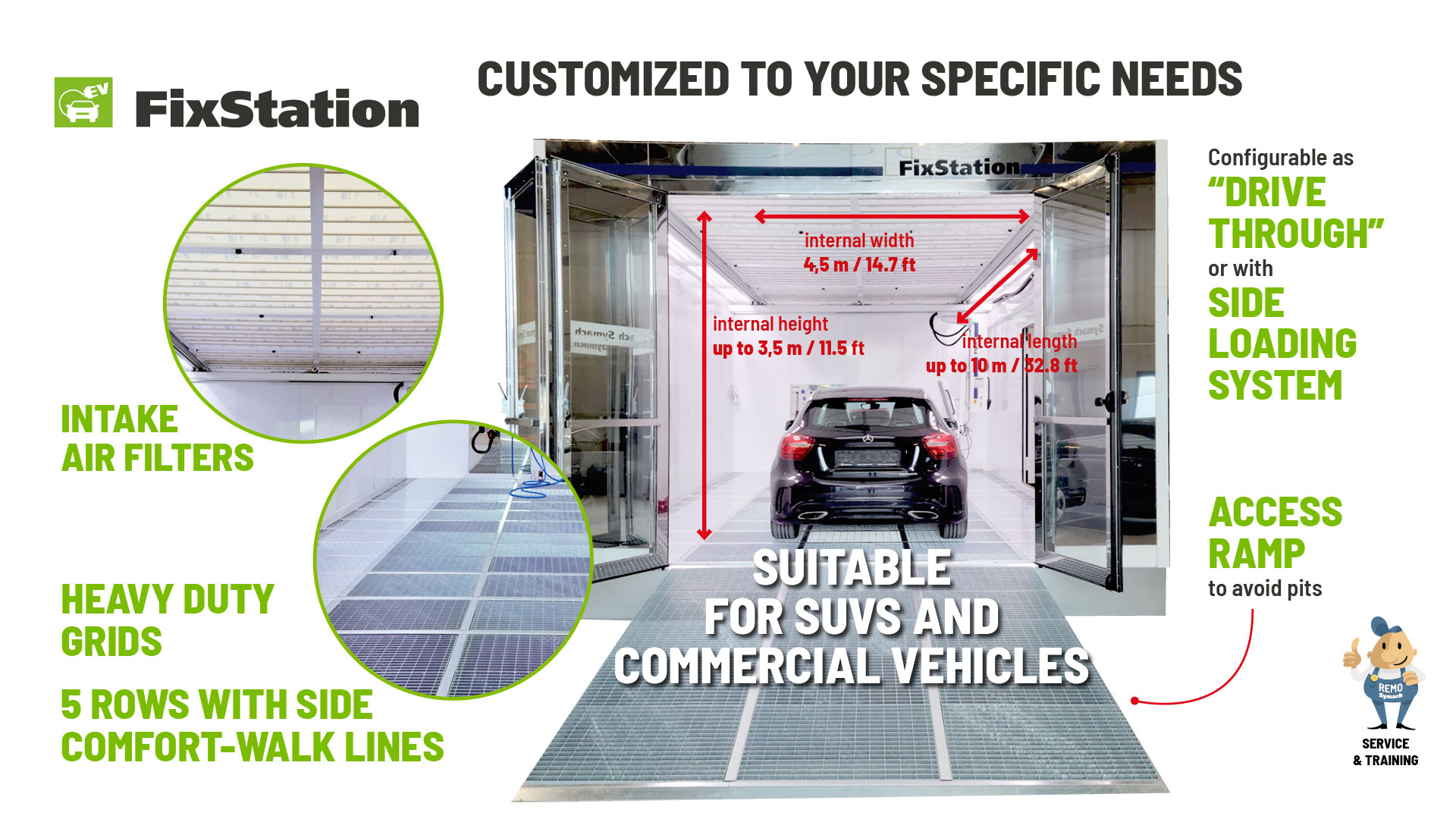

CONFIGURATION

The FixStation customizations:

– two different lengths: 8 m /26.2 ft, or 10 m / 30 ft

– two different heights: 3 m / 9.8 ft or 3.5 m / 11.5 ft,

– one pneumatic side door,

– plenum with air intake, PowerLED lighting and ventilation group

COMPUTER

The FixStation’s computer autonomously handles three distinct programs, eliminating the need for manual operation. It not only selects and activates these programs but also autonomously ramps up ventilation speed when the filters become dirty. These programs are as follows:

1. **Spraying:** This program utilizes 80% of the total ventilation and automatically initiates when the painter begins using the spray gun. It stops when the painting process is completed. This ensures that maximum electricity and gas consumption only occurs during the spraying phase.

2. **Drying with FlyDry robot:** This program employs 40% of the total ventilation to remove gas and solvents generated during the drying process.

3. **Climatization:** This program is exclusive to the version with warm air inlet. It utilizes 30% of the ventilation capacity and automatically initiates once any of the aforementioned phases concludes. This program provides clean and warm air to the painter when preparing the vehicle for painting.

WALL FRAME

The side panel of the FixStation consists of a welded tubular frame. Within the booth, you’ll find a powder-coated metal sheet. In the center, there’s a 5 cm (2 inches) layer of insulation.

CEILING

The ceiling comprises a tubular-welded frame designed to accommodate the filters. These filters are organized into six separate boxes, making it convenient to open them for filter replacements.

BASEMENT

The basement is 50 cm or 20 ” deep and the standard grids support a weight of 850 kg or 1,870 lb per point of 10 ” x 10 ”.

DOORS

The FixStation is equipped with a front pneumatic door, and as an option, a side pneumatic door that operates vertically to minimize the dispersion of dust.

MECHANIC

The standard model of FixStation features a ventilation outlet with a fan that provides 20,000 m3 per hour or 705,000 CFM. Inlet air is sourced from the plenum, drawing air from within the warehouse.

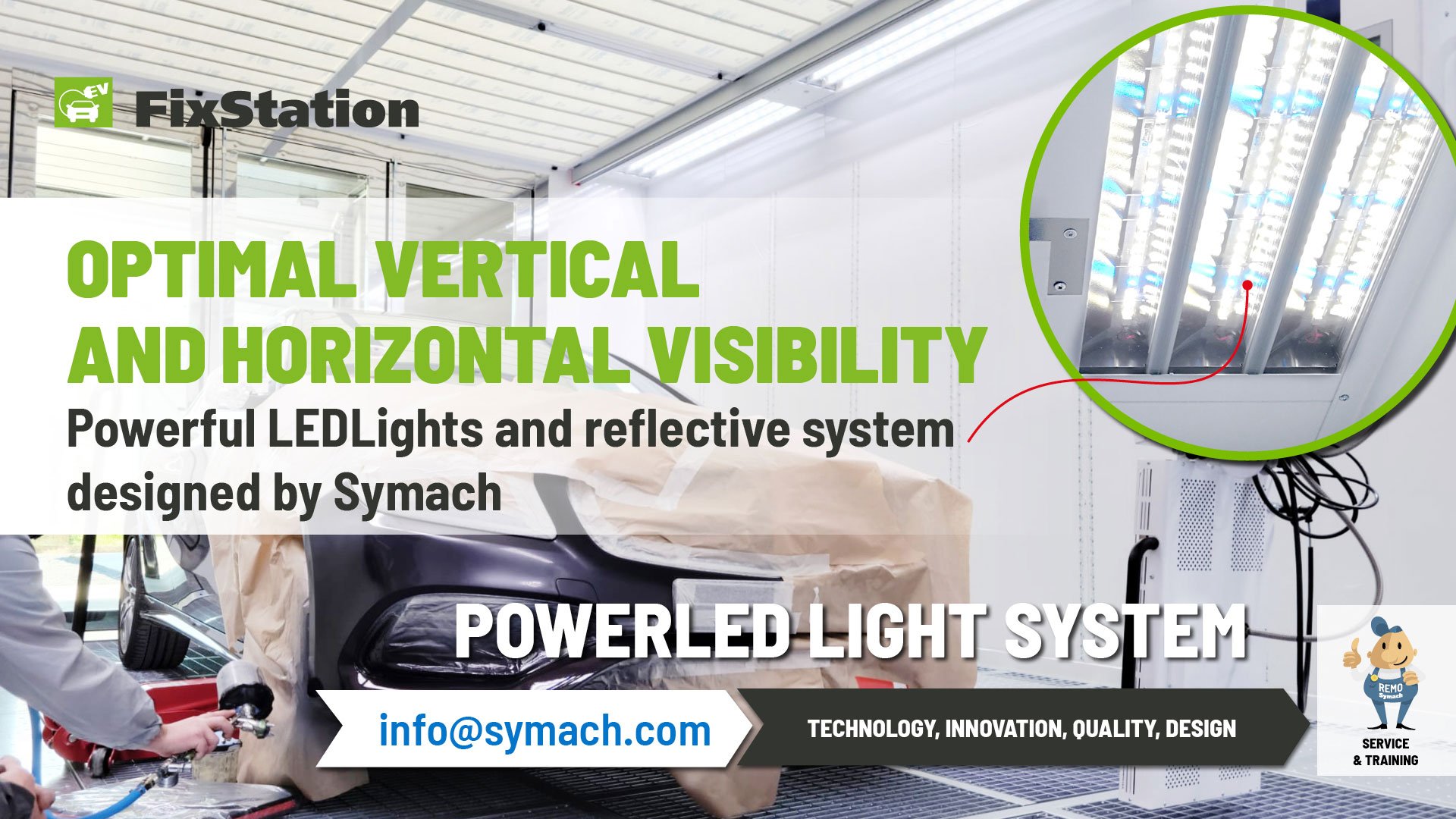

LIGHT

The FixStation incorporates PowerLED, an innovative lamp developed by Symach’s research department. This lamp delivers exceptional lighting performance, featuring a new and exclusive reflector that precisely directs the light beam, covering the entire car from the roof to the vertical bottom side without any scattering. This new lighting solution provides superior quality and power compared to other lights available in the market, benefiting the painter both on the car’s vertical and horizontal surfaces.

FIXSTATION AVAILABLE OPTIONALS

Optional components that can be considered include:

CarLift: the carlift provide convenient access to the underside of vehicles during repairs and maintenance. While not essential, it can greatly enhance efficiency and workflow within the FixStation.

Symach’s PowerLED light system, integrated into the FixStation, offers remarkable illumination for the vehicle, ensuring optimal visibility and an accurate color reference during detailed paint application.

If you opt for the version with a plenum, the FixStation can be equipped with both inlet and outlet features. In this configuration, the ventilation unit is equipped with a mixing valve that regulates the flow of hot and cold air, and it can also include a burner.

This booth incorporates advanced technology and automation that can recognize the specific painting phase being carried out. As a result, the system automatically adjusts its ventilation program accordingly.

FixStation is available in multiple configurations including length and height variables, pneumatic side doors and much more. It’s complementary to the FixLine system.

Symach srl

Symach srl