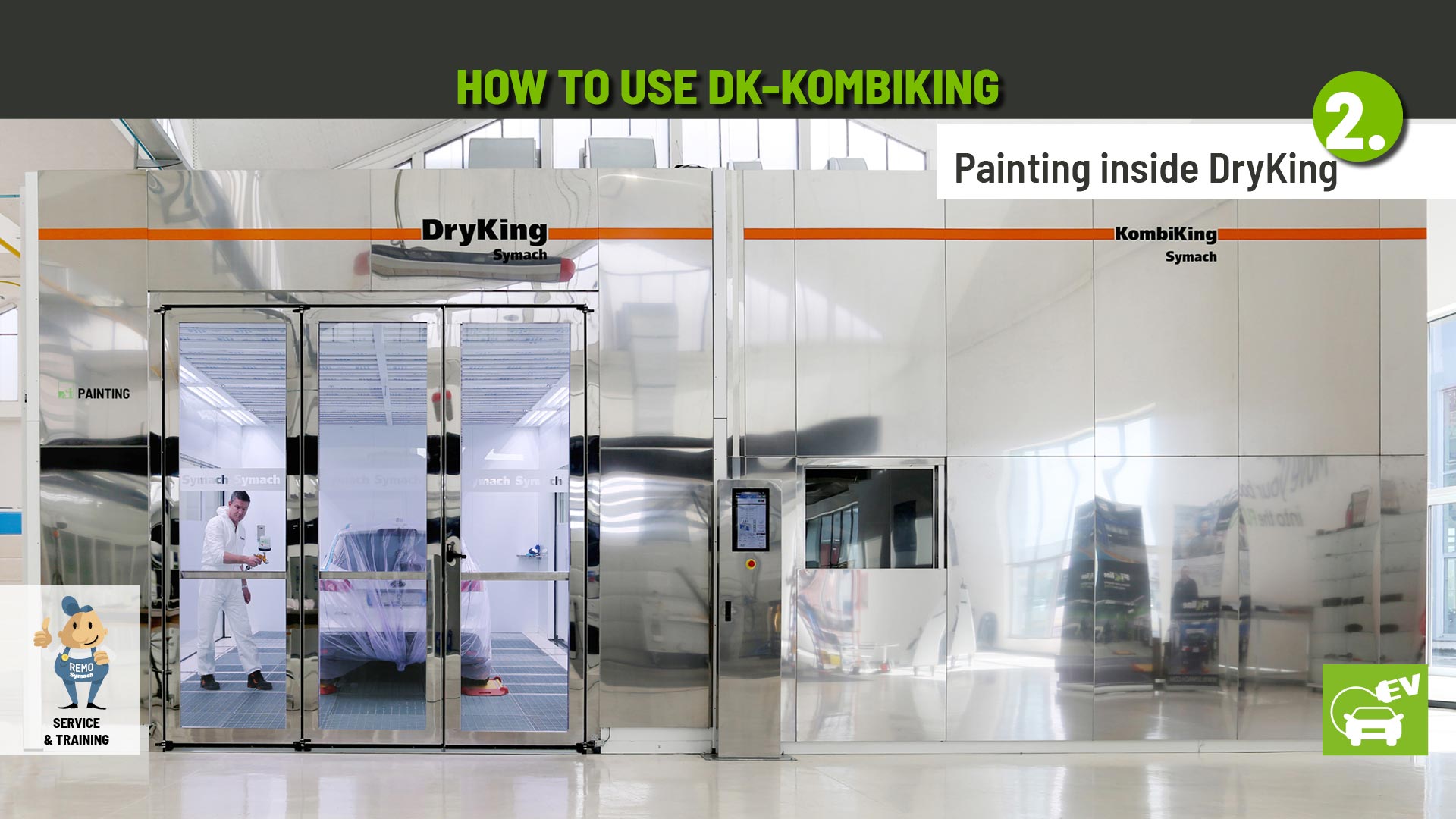

Drying cabin that works in combination with Symach paint booth DryKing

KOMBIKING IS THE INNOVATIVE AND PATENTED DRYING BOOTH BY SYMACH

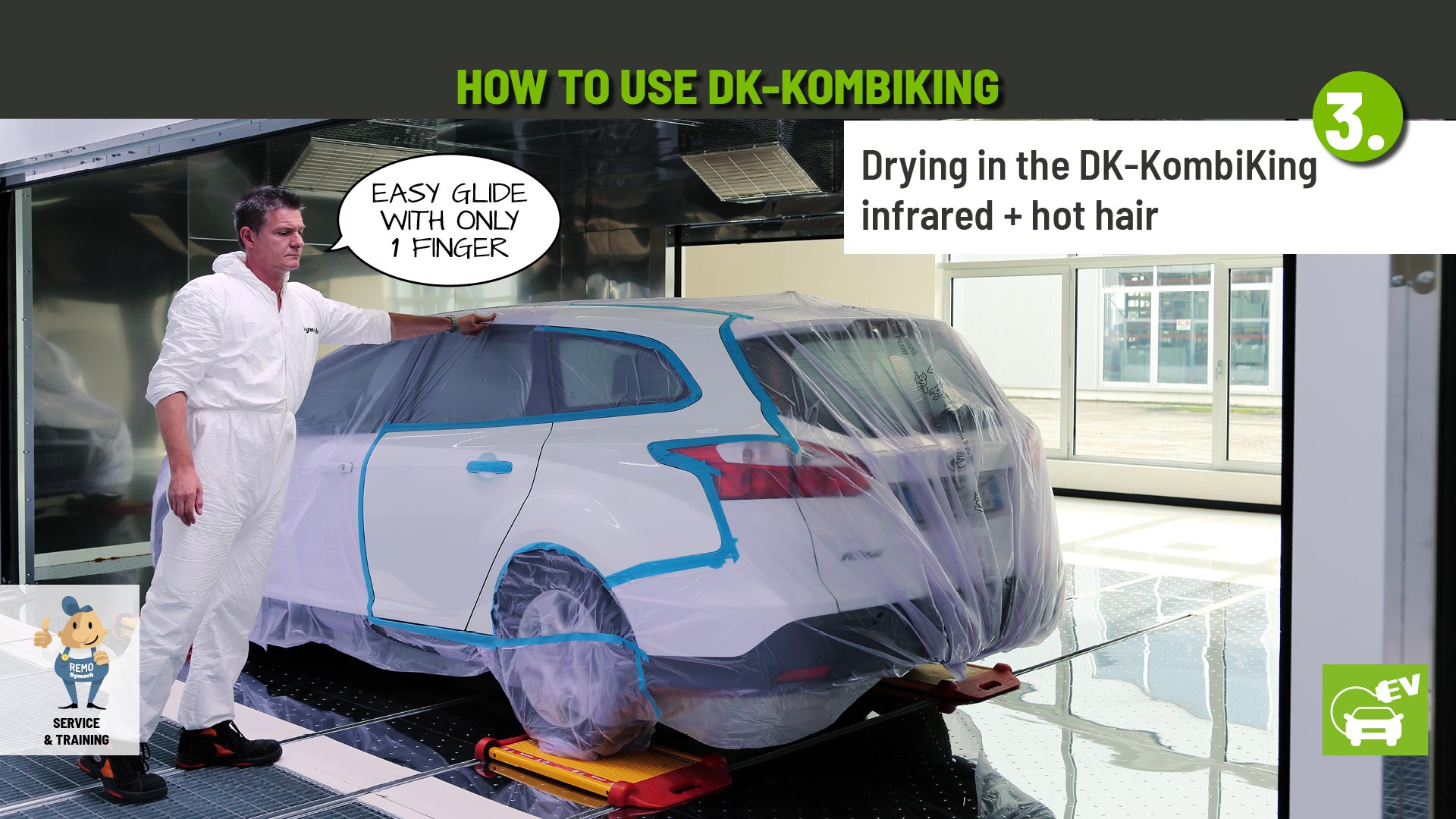

It uses patented IR DryTronic Technology to provide a fast, consistent and reliable drying result. Infrared panels are integrated into the upper sections of the interior walls, ensuring a uniform distribution of infrared waves. These waves are efficiently reflected by the stainless steel lining on the inner surfaces of the walls, covering every part of the painted vehicle with consistent irradiation. Opting for integrated infrared panels in the drying booth’s walls, as opposed to a robotic arch for paint drying, offers a significant advantage – a substantial reduction in drying times. This is achieved by ensuring uniform and simultaneous drying across every part of the vehicle, while with the robotic arch, paint dries progressively as the arch passes over it.

THE DRYTRONIC TECNOLOGY THAT ENHANCES THE DRYING BOOTH

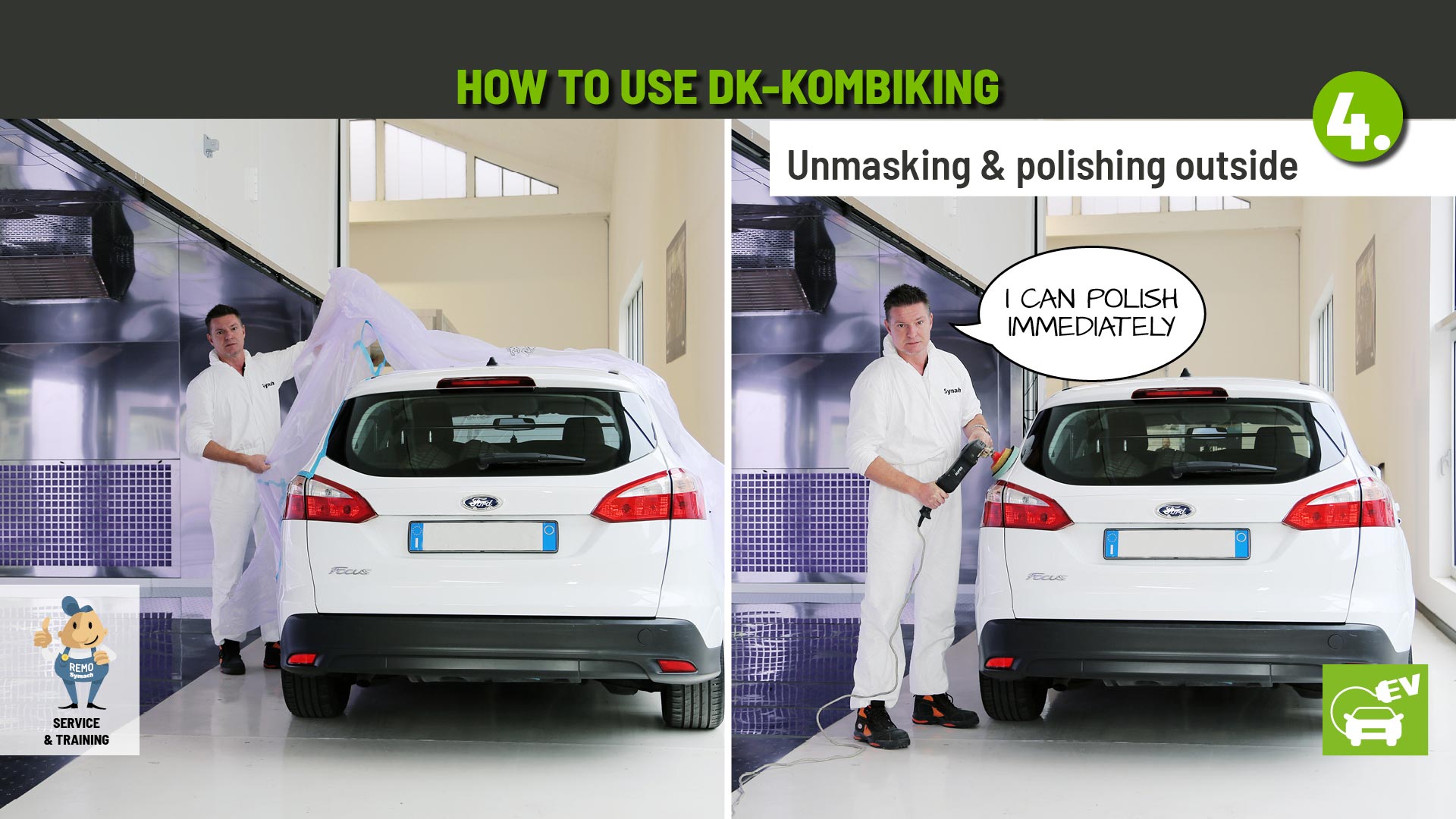

Any paint is dried instantaneously with means of electromagnetic waves generated by a chemical reaction, giving a perfect finish for both water-based and solvent-based products, and allowing sanding and smoothing as soon as the treatment cycle ends. This technology doesn’t rise the temperature in the booth nor on the vehicles, and is perfect for treatments on electric vehicles.

The reduction in the drying and flash-off times given by Symach IR Technology, ensures the body shops to speed up the repair processes while keeping high-end quality results.

GAS CONSUMPTION OF THE DRYING BOOTH

Lowering the time needed to dry paint is also assured by the internal walls in stainless steel: Kombiking booth is an excellent time and energy saver, cutting gas consumption by 93% and time by 74% compared to a normal drying booth. For example, the gas consumption for each car repaired drops from 45m3 for a classic booth versus a 3,21 m3 for the Kombiking. Also, the use of the DK-KombiKing in the drying process allows to dry paint in only 12 minutes and primer in 10 minutes versus the 45 minutes each of a classic booth.

PERFECT FOR ELECTRIC VEHICLES

Furthermore, as well as any Symach bodyshop equipment, Kombiking is EV-Ready.

Low temperatures in the booth and a technology that doesn’t raise interior or car’s platform temperatures, such as the DryTronic technology, are optimal to preserve batteries and electronic systems of modern cars.

Symach systems for the processing of Electric Vehicles are safer, more energy efficient and directly curing vehicle coatings without the excessive heat that conventional bake ovens generally produce.

There is no requirement to change paint products nor increase curing times, that would add time to the repair process.

Drying with DryTronic Infrared technology is the gentle way to refinish electric cars that have sensitive electronics systems; it’s ideal for EVs and hybrids, minimizing the impact on the battery and EV components.

DRYKING-KOMBIKING IN THE SIDE-LOAD FIXLINE SYSTEM

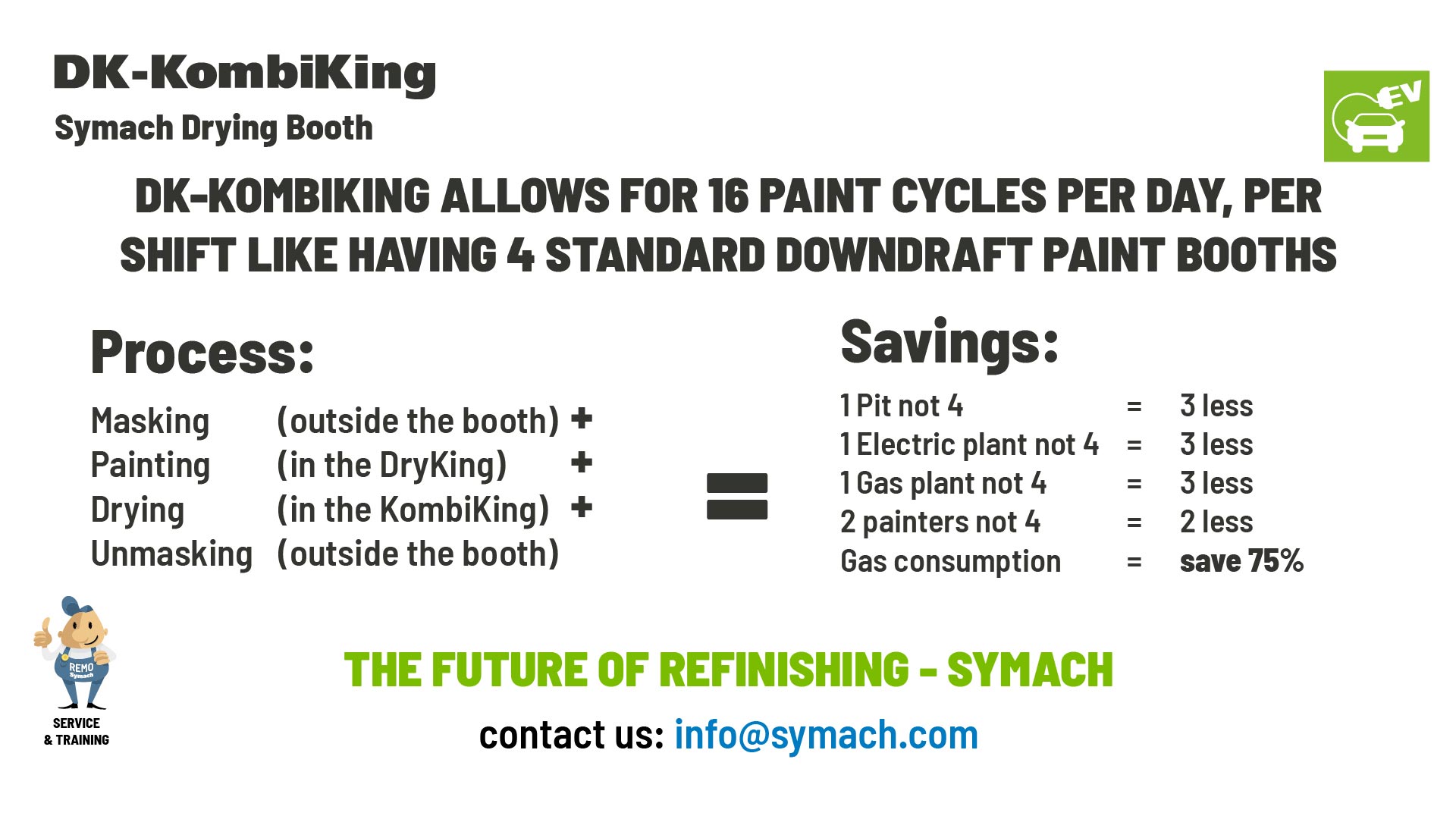

The KombiKing is normally used in combination with the DryKing spraybooth in the Symach side-load FixLine system, the genuine process to repair and paint cars in line.

Tailored for high-capacity body shops and collision repair centers, side-load FixLine systems by Symach enhance operational efficiency and optimize workshop space. These systems facilitate the swift and seamless movement of vehicles between workstations on their integrated track and dolly system.

Side-load FixLine systems can be personalized to suit your workshop’s layout and production requirements. To further enhance productivity, we can customize your side-load FixLine system with extended tracks located outside the paint booths and preparation areas. This innovative approach eliminates the necessity to drive vehicles along the paint line, allowing for full vehicle preparation, including taping, before entering the booth or prep area. This optimization can save you up to 15 minutes per cycle.

Symach offers a complete range of bodyshop equipment along the FixLine, to ensure the best quality of the repair and the healthier environment for the technician to work in.

Thanks to the FixLine system, a body shop can rely on consistent and proven performance to deliver on the business objectives.