Why You Shouldn’t Dry Electric Vehicle’s Paint in a Standard Paint Booth Oven

Introduction

As the automotive industry shifts towards a more sustainable future, electric vehicles (EVs) have taken center stage. These cutting-edge vehicles offer a cleaner and greener mode of transportation, but they also present unique challenges when it comes to refinishing and repainting. One common mistake that some auto body shops make when working on electric vehicles is attempting to dry their paint jobs in a standard paint booth oven. In this article, we’ll discuss why this practice is ill-advised and explore the best alternatives for refinishing and spraying electric vehicles.

The Unique Challenges of Refinishing Electric Vehicles

Electric vehicles, with their advanced battery and powertrain systems, differ significantly from traditional internal combustion engine (ICE) vehicles. These differences extend to the way EVs should be treated when it comes to refinishing and repainting. Here are some reasons why drying an electric vehicle’s paint in a standard paint booth oven is not the ideal approach:

- Temperature Sensitivity: Electric vehicle batteries are highly sensitive to temperature fluctuations. Extreme heat can damage the battery cells, reducing their efficiency and lifespan. When an EV is exposed to high temperatures in a paint booth oven, it can lead to thermal stress on the battery, potentially causing long-term damage.

- High-Voltage Systems: Electric vehicles feature high-voltage electrical systems that power their motors. Introducing high heat near these systems can pose a significant safety risk. The risk of electrical shorts, fires, or other accidents increases when an EV is subjected to high temperatures during the refinishing process.

Alternatives for Refinishing and Spraying Electric Vehicles

Given the unique nature of electric vehicles, it’s essential to adopt alternative methods for refinishing and spraying EVs that mitigate the aforementioned risks:

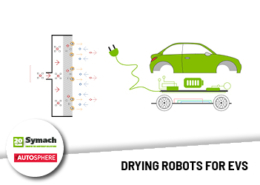

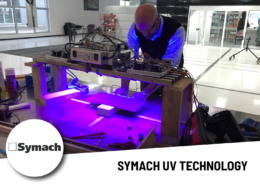

- Low-Temperature Drying: Instead of using a standard paint booth oven, opt for low-temperature drying methods that reduce the risk of damaging the EV’s battery and high-voltage systems. Advanced infrared drying technology and the use of UV basecoat products can be more suitable for electric vehicles.

- Temperature Monitoring: When refinishing an electric vehicle, use temperature monitoring systems to ensure that critical components, such as the battery pack and high-voltage systems, remain within safe temperature ranges. This will help prevent overheating and associated risks.

- Proper Ventilation: Adequate ventilation is crucial when working on electric vehicles. Ensure that your workspace has the necessary airflow to dissipate any fumes or heat generated during the refinishing process, reducing the risk of accidents.

Conclusion

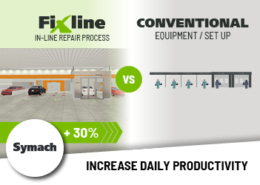

Refinishing and repainting electric vehicles require a nuanced approach due to the unique characteristics of these vehicles. Attempting to dry an EV’s paint in a standard paint booth oven is not advisable, as it can lead to battery damage, safety hazards, and compromised paint quality. To ensure the best results and the safety of both the vehicle and technicians, auto body shops should invest in alternative methods and technologies tailored to the specific needs of electric vehicles. By doing so, they can continue to provide high-quality refinishing and repainting services while keeping pace with the evolving automotive industry.

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl