Prioritizing Workplace Health & Safety: Repairing and Painting Electric Vehicles in a Modern Bodyshop

As the automotive industry continues its shift towards electric vehicles (EVs), it is essential for bodyshops to adapt their repair and painting processes to meet the unique requirements of these vehicles, whilst workplace health and safety must remain a top priority to ensure the well-being of employees and the efficient functioning of the facility.

Understanding the Unique Challenges of Electric Vehicles

Electric vehicles introduce several new challenges to the traditional repair and painting process. These challenges arise due to the presence of high-voltage components, specialized battery systems, and advanced electronics. Technicians working on EVs need to be well-trained and aware of the potential risks associated with these systems to ensure their safety and the proper functioning of the vehicle.

Key Considerations for Workplace Health and Safety

- Training and Certification: It is crucial for technicians to receive adequate training and certification specific to EV repair and painting. This includes understanding the unique safety procedures, handling of high-voltage components, and identifying potential hazards associated with EVs. Regular training updates are essential to stay up-to-date with the evolving technology.

- Personal Protective Equipment (PPE): Technicians should be trained to the use of appropriate PPE to ensure their safety while working on electric vehicles. This may include insulated gloves, safety glasses, face shields, and flame-resistant clothing. PPE should be regularly inspected, properly maintained, and replaced when necessary.

- Ventilation Systems: Symach Dryking spraybooth and Kombiking drying cabin are known for their advanced ventilation systems, which play a crucial role in maintaining a safe working environment. Adequate ventilation helps control hazardous fumes, particulate matter, and volatile organic compounds (VOCs) released during the painting process. Regular maintenance and filter replacements are necessary to ensure optimal performance.

- Hazardous Materials Management: Bodyshops working with EVs must have proper procedures in place for the storage, handling, and disposal of hazardous materials such as lithium-ion batteries and other chemical substances. Strict adherence to local regulations and guidelines is essential to minimize risks and protect the environment.

In light of workplace health and safety considerations, it is important to address the unique challenges posed by electric vehicles (EVs) during the paint and curing phase of repairs. One significant aspect is the sensitivity of high-voltage batteries used in EVs, which cannot withstand high temperatures typically involved in the refinish process.

Symach systems designed for processing electric vehicles offer a safer and more energy-efficient solution. Thanks to the use of the patented infrared DryTronic technology developed by Symach and installed in its drying cabin, the Dryking-Kombiking system of paint and drying booths enable the direct curing of vehicle coatings without relying on excessive heat generated by conventional bake ovens. This eliminates the risk of damaging the high-voltage batteries while ensuring extremely quick, efficient and effective curing.

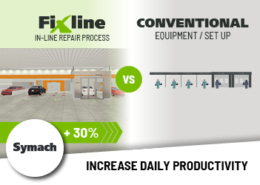

One advantage of using Symach systems is that there is no need to change paint products or extend curing times, which could potentially prolong the repair process. The systems are specifically designed to work seamlessly with existing paint products and accelerate curing times, allowing for a smooth transition in the repair workflow.

The use of DryTronic Infrared technology in the drying process provides a gentle approach to refinishing electric cars. This technology is particularly suitable for EVs and hybrids, as it minimizes any adverse impact on the battery and other EV components.

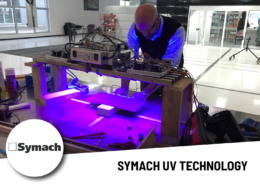

Within the BaseTron preparation bay along the paint line, Symach provides infrared technology for primer application and drying process too. The process involves the use of infrared panels integrated into the drying robot called FlyDry. Additionally, the FlyDry robot can accommodate UV technology for drying UV coatings. By combining the power of infrared and UV technologies, Symach enhances production efficiency while ensuring safe and optimal curing specifically tailored to electric vehicles (EVs).

The controlled heat generated by infrared panels and the rapid curing capabilities of UV technology work harmoniously to meet the specific requirements of EV paint applications. This synergy ensures consistent and high-quality finishes, while also safeguarding the sensitive components and electronics of the electric vehicles.

Symach IR and UV systems offer a reliable and efficient solution for repairing and refinishing electric vehicles. By eliminating the need for high temperatures during the curing process, thanks to the utilization of DryTronic Infrared technology, Dryking-Kombiking booths and the FlyDry drying robot ensure the safety of high-voltage batteries while maintaining the quality and timely completion of autobody repairs.

With Symach’s advanced solutions, bodyshops can efficiently and effectively handle the unique challenges posed by EV paint processes, contributing to enhanced productivity and customer satisfaction.

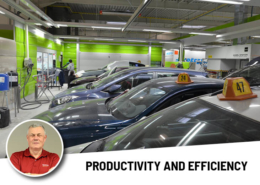

A testimonial contribution by Aaron Scagliotta, owner of Reenew Collision Repair Center, 1 Altona Street, Bibra Lake, WA, Australia, Western Australia

“As the first Collision Repair Centre in Australia to specialize in EV’s, I took into consideration my paint curing options for the process of repair very seriously.

Ultimately Symach was the best decision for us. We took into consideration the lower exposure time to heat with the extremely fast drying system, as well as the versatility that comes with the option of UV curing for the priming process.

An additional bonus of course is that the system allows for “Continuous Piece Flow.” Which allows the vehicle to move through the process quickly (without driving)

Additionally because of this system, the number of staff required to produce is significantly less, hopefully leading to better outcomes in the paint department.”

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl