Symach Infrared & UV Technologies for curing and drying of paint

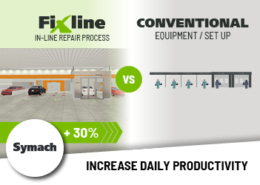

Efficiency and quality are crucial in autobody repairs, including the curing and drying of paint. However, this process has traditionally been time-consuming and prone to errors. Symach’s patented DryTronic infrared technology has revolutionized the collision repair industry by accelerating paint drying and curing processes.

INFRARED TECHNOLOGY

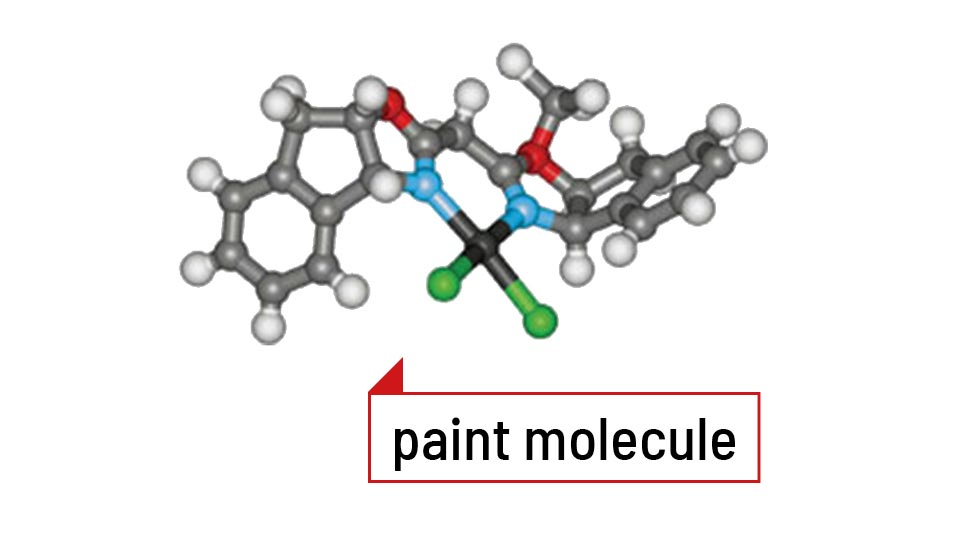

The DryTronic system utilizes short-wave infrared energy to rapidly cure paint, significantly reducing the time required. It employs a patented exothermic catalytic chemical reaction that combines hydrogen and oxygen, generating different infrared wavelengths with a broad spectrum. This process ensures safe operation even in the presence of flammable substances, and it’s ATEX certified. The DryTronic system offers numerous benefits, including improved productivity, enhanced paint quality, and reduced energy consumption.

The DryTronic generator releases more than 85% of the energy contained in the paint molecule by emitting a selective spectrum of electromagnetic waves. The Wave Length Control System (WLC) allows for precise management of wavelengths based on the paint brand and type. The DryTronic technology penetrates directly into the paint molecule, instantly drying it. For example, clear lacquer can dry in as little as fifty seconds of exposure. It provides consistent drying results for various paints, materials, and thicknesses.

Symach’s DryTronic infrared technology cures paint in minutes, compared to traditional methods, enabling bodyshops to complete more jobs in less time. The precise temperature and intensity control ensures uniform curing, resulting in flawless finishes and reduced rework. Additionally, the system’s energy-efficient approach reduces operating costs and promotes environmental sustainability.

Symach’s infrared technology is safe for human health, with no side effects or risks to the eyes. The system’s invisible wave spectrum poses no harm, even with prolonged exposure. It cures any type of paint at low temperature, being suitable for curing all electric vehicles.

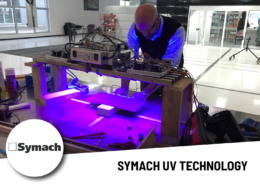

UV TECHNOLOGY

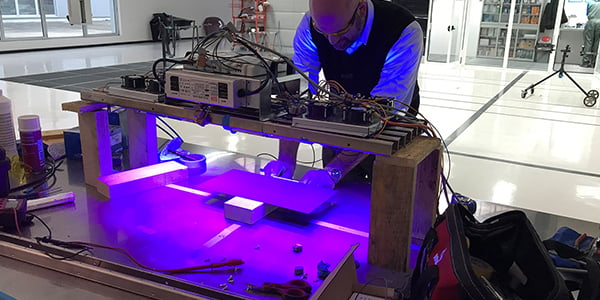

Additionally, alongside Symach’s infrared technology, the company also offers advanced UV technology for drying UV products. UV technology has become increasingly popular in recent years due to its fast and efficient curing properties.

Symach’s UV technology utilizes ultraviolet light to cure UV-based paint and coatings in a matter of seconds. The UV lamps emit high-intensity UV light that triggers a photochemical reaction, instantly drying and hardening the paint surface. The LEDs used are of different wavelengths all in the UV-A segment, these are assembled along a line of reflectors studied and designed to achieve the fastest and most efficient drying result on the market.

They are controlled by an electronic board with a temperature control device that close the electric power in the event of the device overheating due to prolonged and continuous use of it. Symach installs the LEDs on an aluminium support equipped with a heat sink, allowing prolonged use of the lamp also for drying several car panels in sequence

The UV technology by Symach provides several advantages. Firstly, it ensures a complete and thorough cure, resulting in a durable and long-lasting finish. The precise control over UV intensity and exposure time guarantees consistent and uniform curing across the entire painted surface, minimizing the risk of imperfections or incomplete curing.

Symach’s UV technology is also environmentally friendly and energy-efficient.

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl