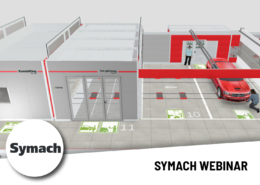

Webinar – Opening or Renovating Your Bodyshop?

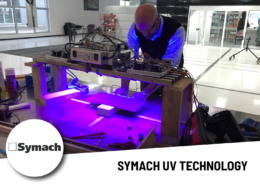

Symach is leading the way in sharing best practices to bodyshop owners and site mangers to renovate their current shop or open a new one; regardless of the size of the shop.

Based on a real example for a mid-sized shop planning to produce 10 job cycles per day, Osvaldo Bergaglio, CEO & Founder of Symach, explained bay by bay (stall by stall) the added value of installing Symach FixLine, the lean in-line repair process for bodyshops and car dealers.

Osvaldo has an holistic view of the collision industry and is passionate about sharing his know-how built in 40 years’ experience in this field.

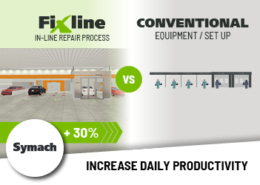

FixLine is a tailored solution that repairs from 5 to an unlimited number of job cycles per day. It increases productivity, quality and speed of every repair, to maximize capacity per square foot/meter.

Symach offers a complete service from project management, layout design, equipment manufacturing and installation, to personalized training. Its international Sales Team starts designing the new project, including data analysis of your current shop to understand at which step of the repair process efficiency and profitability can be improved.

Webinar Key take away :

Chapter 1

- Data analysis to define the right number of car spaces and number of technicians. Data includes number of repairs, number of technicians, number of working shifts hours and labor cost.

- Paint brand, used to establish the proper drying equipment

- Understand of average dimension of damages to repair

Chapter 2

- Define a new process, including average time per repair and bodywork organization

- Financial data (revenue, margin, labor cost, equipment depreciation, ROI)

Chapter 3

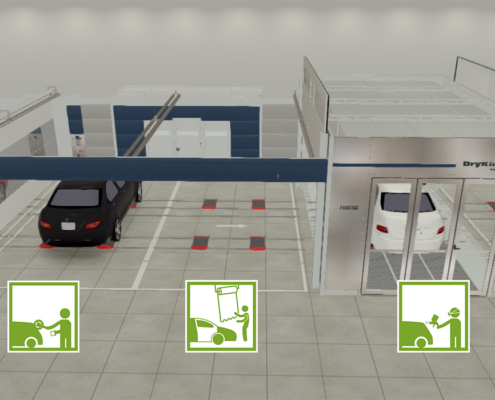

- Design your new shop layout, based on the segmentation of damage and repair process flow

- How to tailor Symach equipment based on future production needs

- Repair process management phase by phase, from metal work to car wash and detailing using Symach FixLine, the in-line repair process to optimize efficiency and productivity, for long term sustainability, regardless of the size of the shop

Opening or Renovation your bodyshop? Contact us!

Subscribe to Symach Newsletter

February 2021

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl