Symach Breaking News 08 | December 2022

Symach customer journey begins with the understanding of customer’s needs and objectives, in line with shop size and market segment. We are happy to share with you the real steps of this journey made by concept, projection, layout, production, installation, training, relationship, magic and stories.

LATEST INSTALLATION

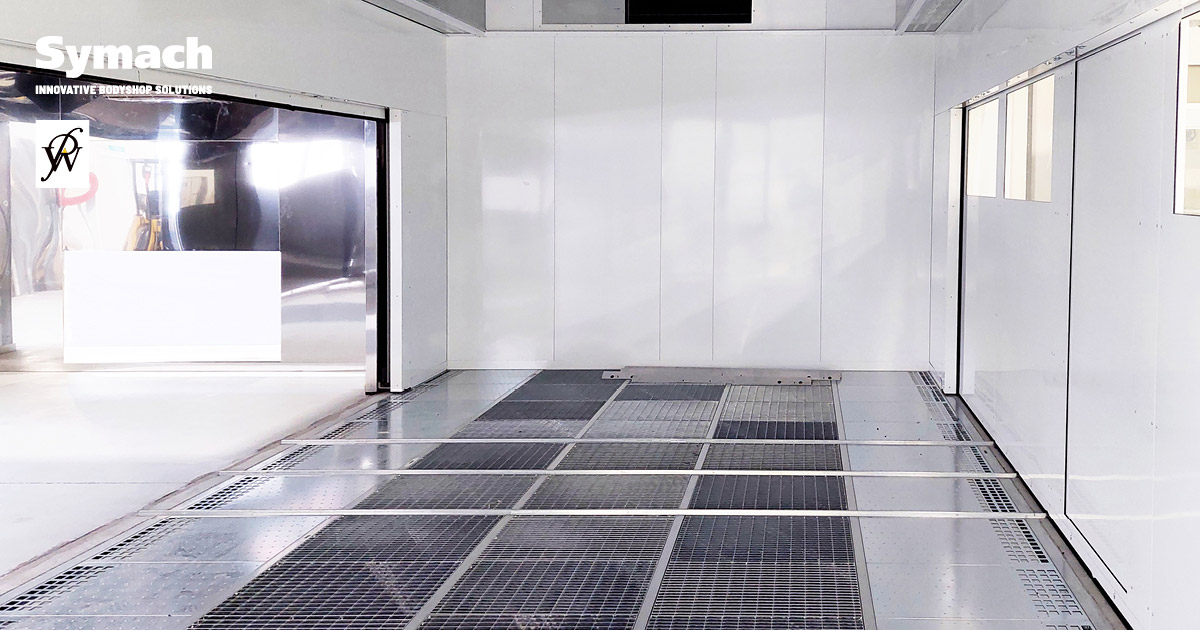

Peter Wilkinson & Co Smash Repairs – Welshpool, Australia.

Thanks to this Fixline the bodyshop will be able to do to up to 16 job cycles a day. To reach that number,Peter Wilkinson has been equipped by Symach with:

- DryKing spray booth

- DK-Kombiking drying cabin

- Preparation bay with Paint Window Extraction, FlyDry Hybrid drying robot and electric Curtains

- Paint Mixing Room

- ServiceColumn with MultiBox and Vacuum Sanding System

- PowerLED light

- CarMover System

LATEST INSTALLATION

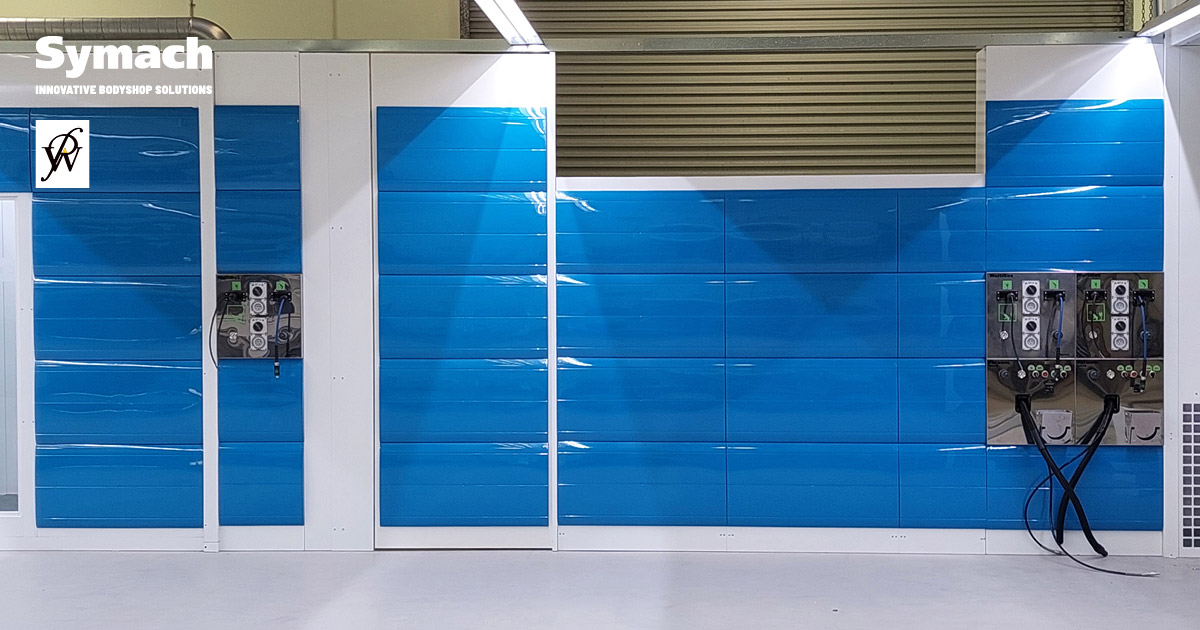

Tamms (Australia).

Installation completed for a new Symach FixLine system for TAMMS Accident Management in Melbourne, AUS. With this FixLine, the collision repair facility will repair up to 10 cars per day, thanks to the following equipment:

1 DryKing

1 PrepTron with electric Curtains

1 BaseTron with 2 Paint Window Extraction

1 PaintMixingRoom

1 FlyDry Hybrid

PowerLED lights

CarMover

LATEST INSTALLATION

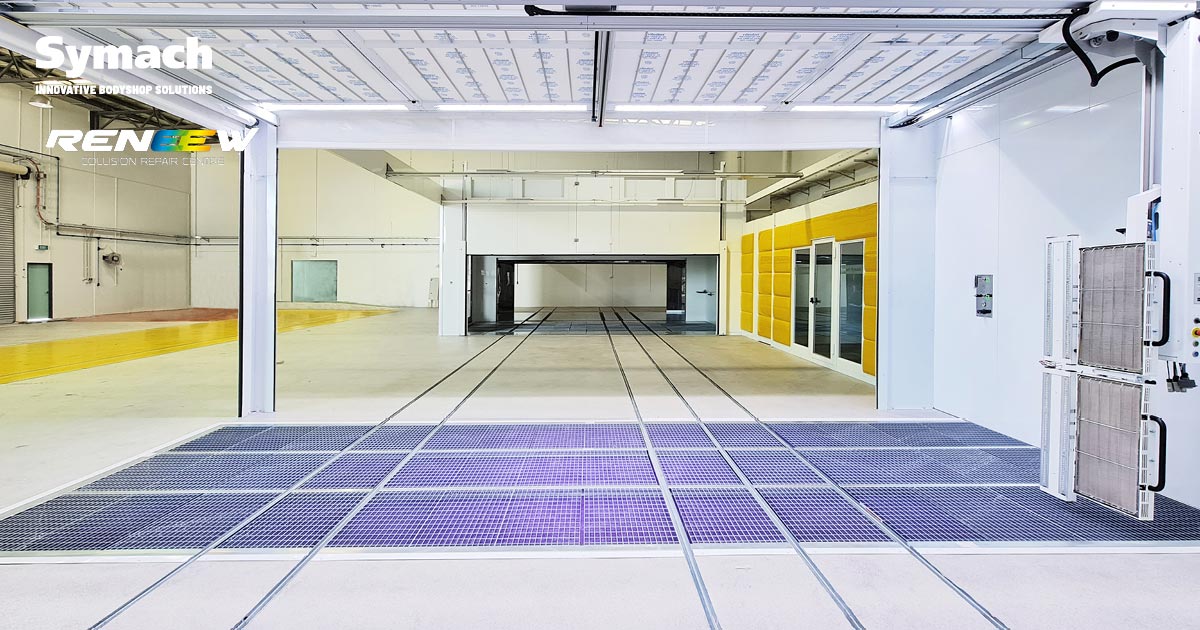

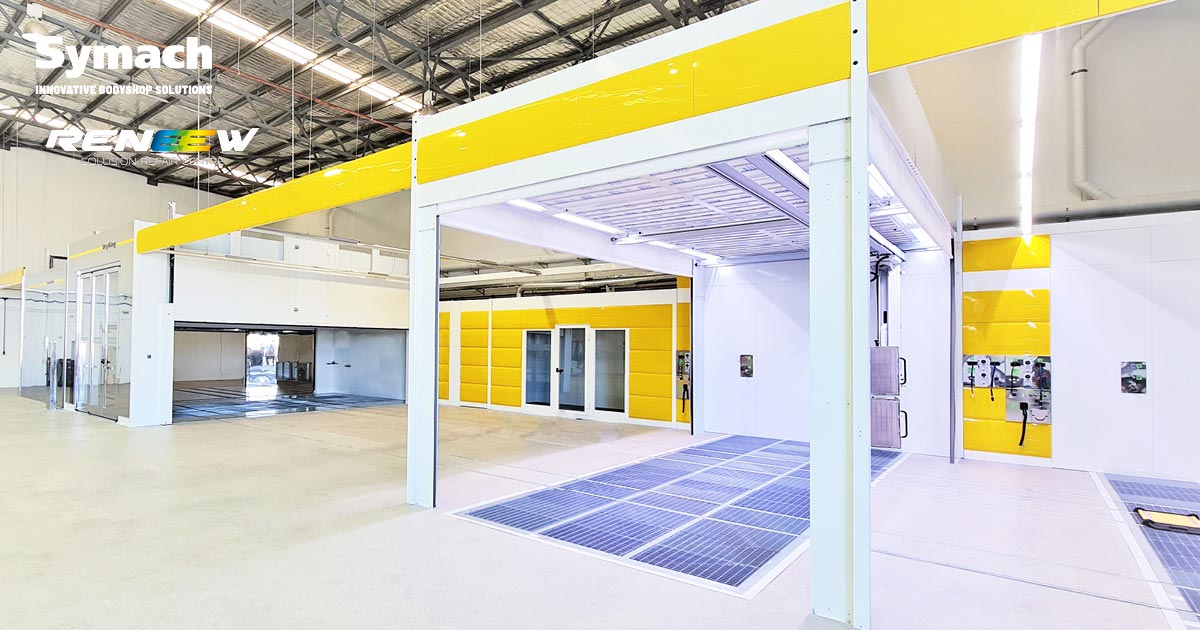

Reneew Collision Repair Centre (Australia).

Symach recently completed the installation of a 16 jobs per day FixLine at Reneew Collision Repair Centre. Aaron Scagliotta and his father Basil installed their second FixLine system, the Symach in-line car repair process.

- DryKing spray booth

- DK-Kombiking drying cabin

- BaseTron preparation bay with FlyDry Hybrid drying robot

- Paint Mixing Room

- MultiBox and Vacuum Sanding System for 2 operators

- ServiceColums with MultiBox

- PowerLED light

- CarMover System

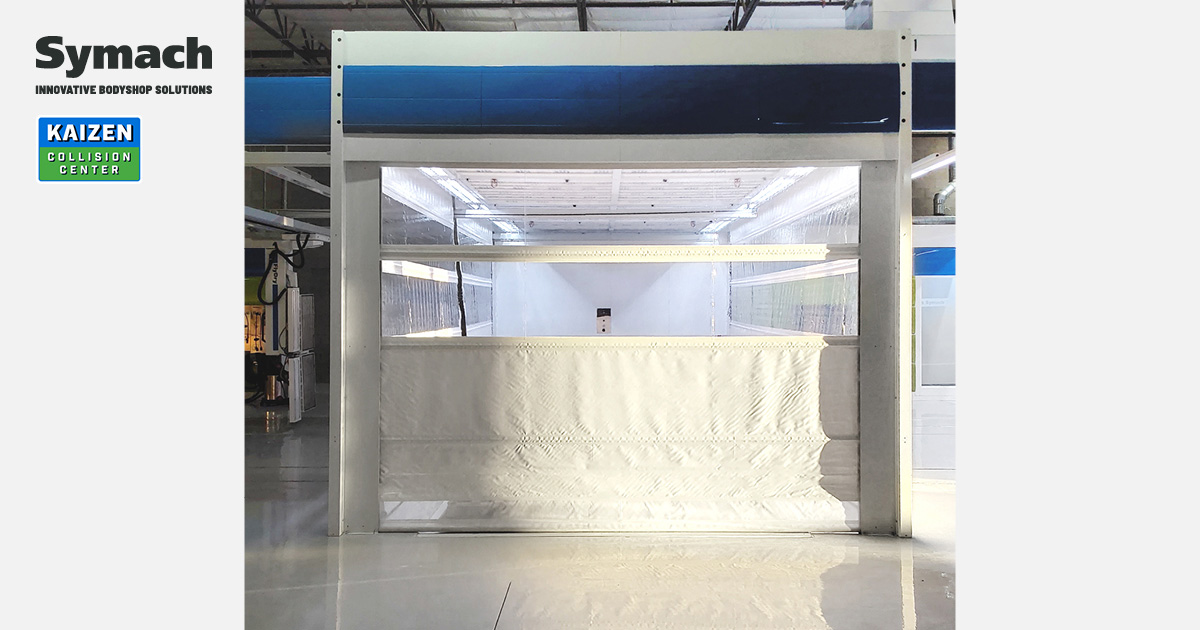

LATEST INSTALLATION

Kaizen Collision (USA).

Symach recently completed the installation of a Fixline equipment that will allow the new Kaizen Collision Center site in Queen Creek, AZ, to do up to 8 jobs per day.

- DryKing spray booth

- BaseTron with FlyDry drying robot

- Paint Mixing Room

- CarWash

- MultiBox and Vacuum Sanding System for 2 operators

- ServiceColums with MultiBox

- PowerLED light

- CarMover System

INSTALLATION IN PROGRESS

Biltrend Harstad (Norway).

Symach’s installation team is currently working in Norway to install a brand new FixLine system in Harstad: the collision repair shop’s name is Biltrend Harstad. The owner, Biltrend Co., already installed a FixLine system in home town Tromso, Norway, some years ago, the shop’s name is Bilskadesenteret Tromso.

In this new collision repair shop, they decided to install Symach Dryking-Kombiking system: the Dryking classic spray booth, and the Kombiking drying cabin combined, to produce up to 16 jobs a day.