Modular Paint Mixing Room

HOW WE BUILD THE PAINT MIXING ROOM

The Symach Paint Mixing Room utilizes a modular panel system called ModulBlock. These panels are of standardized dimensions, measuring 1 meter in width (or 40 inches) and 3 meters in height (or 120 inches). What makes this system exceptional is its modular design, which permits customization to suit specific length and width requirements. Thanks to the flexibility of the ModulBlock system, the Paint Mixing Room can be adjusted to accommodate any desired dimensions.

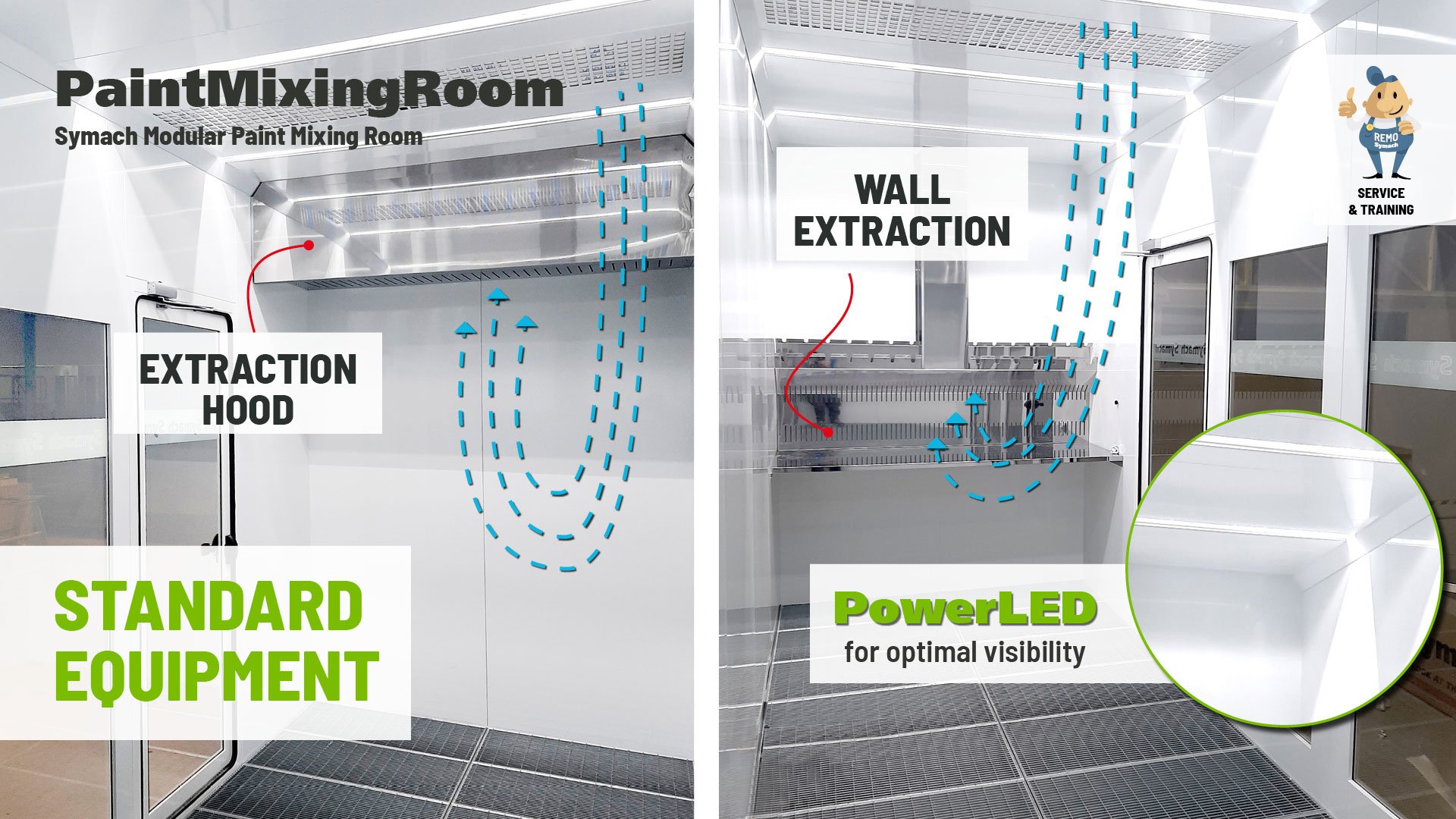

The Paint Mixing Room includes the ventilation unit, the PowerLED lighting system, and an electric plant that automatically manages air extractions, lights and electric power plugs.

AVAILABLE CUSTOMIZATION OPTIONS

- glass doors or glass windows

- gun washing machines (not provided by Symach)

- mixing color machines (not provided by Symach)

- stainless steel table

- extraction hood above the gun washing machine

- vertical extraction on the stainless steel table

- gridded floor over the pit to collect the paint drops

Discover our wide range of bodyshop equipment and the FixLine system.

CONFIGURATION

The PMR is available in any size needed because it is a modular system composed from several panels of ModulBlock. The ideal size is 6/7 m (20/23 ft) long and 2 m (6.6 ft) wide. The ModulBlock panel is 1 m (40″) wide and 3 m (120″) high. It is available in three different versions:

– The first version is closed on both sides, with metal foil inside that is colored white with powder coating and with powder coating and the external side is in CoverTop, a plastic panel in ABS.

– The second version is a tempered glass window that is open.

– The third version has a glass door with an emergency handle and an automatic closing.

PANEL MODULBLOCK

The ModulBlock panel is a tubular-welded frame on one side and a painted metal powder-coated sheet on the other. In the middle, there is 5 cm or 2 ” of insulation and on the external side there is the CoverTop, an ABS plastic panel available in eight different colors.

The ModulBlock panel has a glass window and door is a tubular-welded frame with glass inside.

FLOOR

The PMR floor is in pedestrian grids with a metal box pit underneath to collect the paint spillage.

CEILING

The PMR ceiling is a tubular-welded frame to support the filter for the inlet air and the PowerLED lights.

EXTERNAL COVERTOP FINISHING

The outer covering of the PMR consists of CoverTop panels, made in ABS injection plastic mold, which can be opened and closed.

AIR EXTRACTION

The PMR has two air extraction units: one is a stainless-steel hood installed above the gun washing machine and the other one is a stainless-steel box with grids installed all along the base of the paint table. The two extractions merge into one duct for the final extraction.

TABLES

The PMR has two stainless steel tables:

– one is for preparing color and paint with a size of 200 x 75 cm (80 x 30″)

– the other one is for the mixing scale with a size of 100 x 75 cm (40 x 30″)

EXTERNAL PLANT AND LIGHTING

The PMR has an electric plant that automatically manages two extraction fans, the lights and the electric power plugs. As part of this procedure, electric power can only be supplied when the room has been cleaned from the possible presence of solvents gas.

The PMR uses PowerLED lighting that offers superior light performance in intensity, reaching an average of 1.300 – 1.500 Lux and also a color quality of 5.200 Kl°.