Written by Ed Attanasio

Every year at SEMA, the industry gets to see all the newest technology, and if you’ve been in it for any significant amount of time, you have witnessed the development of new tools and equipment at a rapid rate.

It’s no longer an evolution, but more like an explosion!

Innovators have always led the way in every industry by taking chances and pursuing ideas others thought were outlandish. When Thomas Edison unveiled the lightbulb, people called it a “conspicuous failure.” When bicycles first hit the market, someone wrote they would doom the popularity of the wheel forever. And when the first cheeseburger was invented in 1934, one critic described it as “bizarre” and predicted the concept would flop.

But, obviously, we now use lightbulbs, ride bikes and eat cheeseburgers—in fact, I did all three the other day.

For more than a decade, Symach in Bologna, Italy, has been producing innovative body shop solutions for the collision repair industry. They design and manufacture everything they sell, rather than using third-party companies to assemble packages of tools and equipment.

When you sign on the dotted line with Symach, it’s like taking on a very sophisticated partner, because they play a major role in literally every aspect of your production.

For 20 years, Symach has helped shops switch from conventional repair processes to an innovative lean process using leading-edge technology.

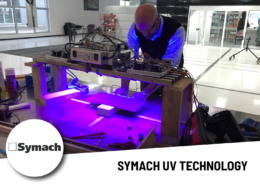

Owner Osvaldo Bergaglio founded the company two decades ago to embark on a research project that led to the development of the DryTronic system, which uses cutting-edge technology to dry automotive paint. It was an immediate success and today, body shops all over the planet use it.

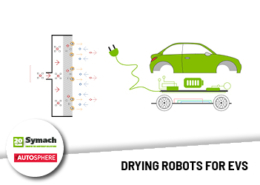

Symach’s DryTronic drying technology allows automotive paint to cure in less than a minute. In 2002, Symach started the production of RoboDry, its first robot for automotive body shops, and developed a quick new process to spray and dry every brand and type of automotive paint, Symach Paint Application Process (SPAP).

Symach’s curing systems are well-known for being green and can reduce a shop’s energy consumption by up to 90%. It reduces a vehicle’s actual time inside the shop by up to 40%, and will significantly reduce an average of three to four hours in labor cost per repair.

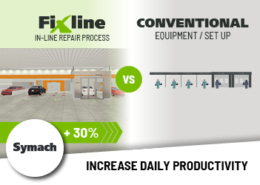

In 2010, Symach began featuring a new repair process, FixLine, which reduces the actual throughput time inside the shop by 1.5 to two days, while eliminating three to four hours in labor costs per repair.

Symach’s FixLine process is slashing cycle time like never before.

“We have developed a system where it moves the car through the process without interruption, as opposed to the stop-and-start conventional way of fixing vehicles,” Bergaglio said. “In your standard shop, cycle time is four to six days and we do the entire repair in one day.”

Everything the company makes, including spray booths, drying robots, UV lamps, LED shop lighting, paint mixing rooms and the FixLine conveyor system, is designed and built using the highest quality components. All equipment is produced at Symach’s headquarters and subsequently installed by the company’s trained experts and followed by on-site personalized training.

In 2016, Symach moved into its new 161,500-square foot factory in Calderara di Reno, Bologna, Italy. Today, the company has more than 30 employees as part of its international team, which includes installers, engineers and trainers.

In 2016, Symach moved into its new 161,500-square foot factory in Calderara di Reno, Bologna, Italy. Today, the company has more than 30 employees as part of its international team, which includes installers, engineers and trainers.

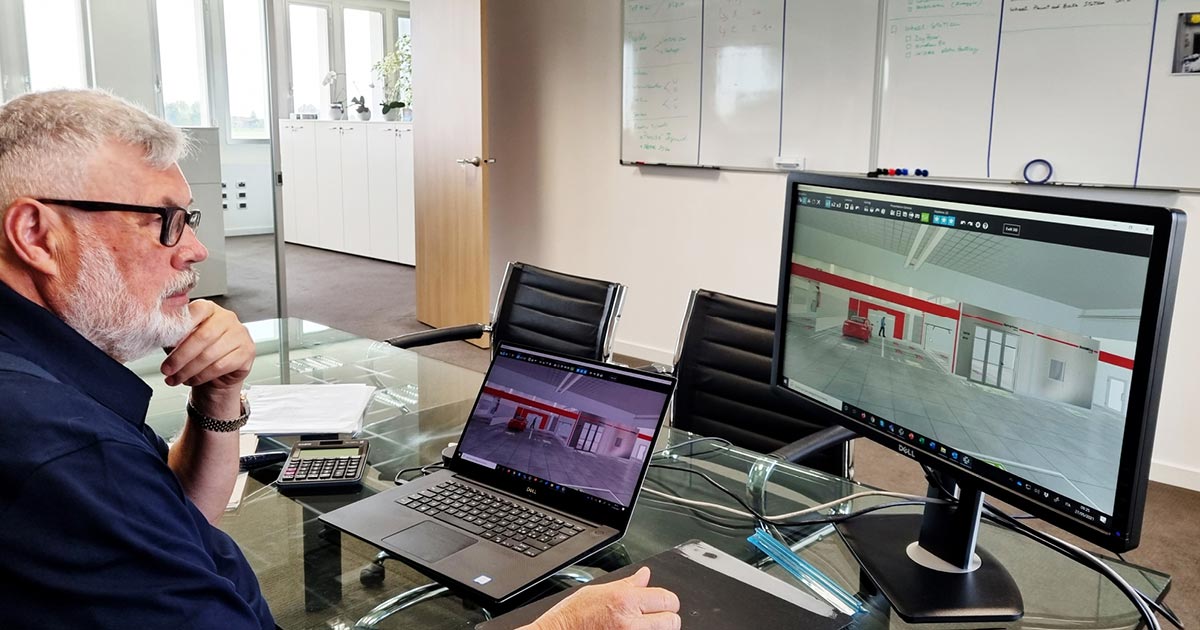

Once a body shop owner decides to become a Symach shop, the company manages the body shop conversion from a conventional process to the FixLine process.

Symach is more than a simple equipment manufacturer; it is a collision repair solution provider with a profound understanding and knowledge of the automotive collision repair process.

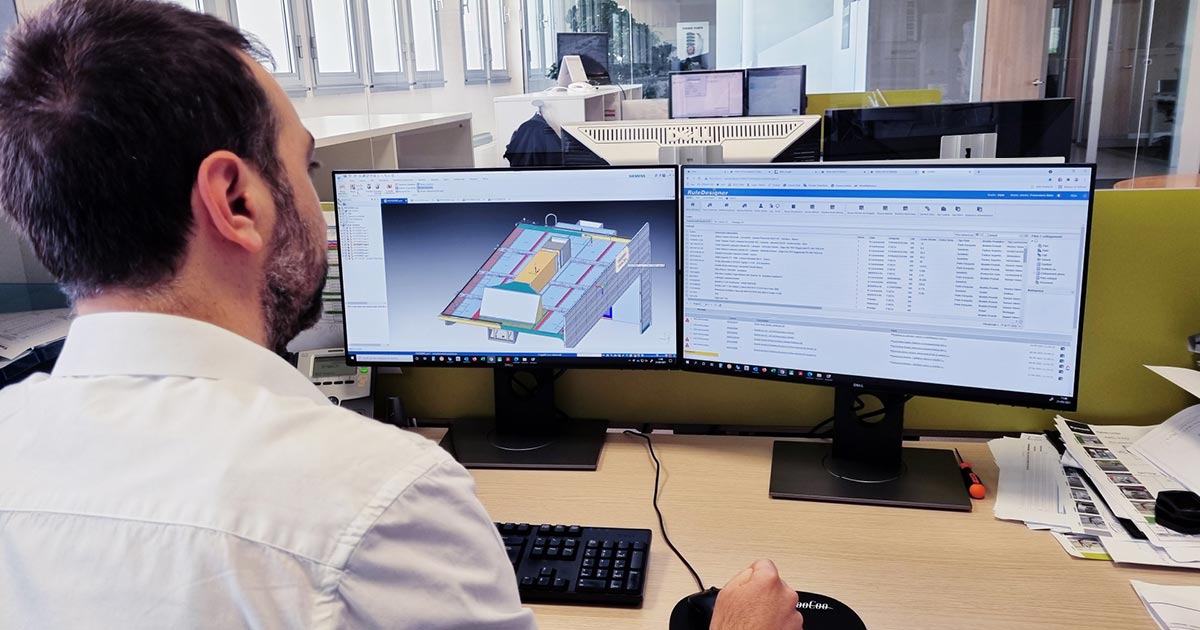

Symach knows every shop is different, so Bergaglio first analyzes the business before devising a custom solution based on the types of cars it repairs.

“We break it down into four categories—classic cars, prestige cars, reconditioning or fleets,” Bergaglio said. “We can work for any body shop or collision center in those categories, but they are completely different in …some ways. Our approach is to look at the business model, look at their data and the activities in the shop. We’ve developed some software that allows us to do the math and design the shop floor for optimum efficiency.”

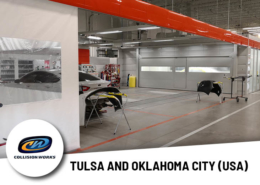

If you want to get a glimpse into the future of the collision repair industry, all you have to do is look at what Symach is doing today. Currently, Symach has sold more than 2,600 robots and more than 150 complete new automotive body shops with the new Symach FixLine process in Europe, the Middle East, Australia and North America, starting in 2015.

Bergaglio and his team are passionate and driven to innovate and invent new products that can wow the industry and change the way we fix cars.

“We unveiled seven new products this year and hope to continue at this pace,” he said. “Everything we do is new and different and like nothing else on the market. Once you are a Symach customer, you won’t be able to go back to the old ways. We create technology that doesn’t follow trends; it begins new ones.”

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl