3D Auto Body’s 7th Location Able to Complete Repairs Faster with Symach Technology & Equipment

When Dave Niestroy was a teenager, he had a passion for repairing cars. Over the years, he built a business in Philadelphia, Pennsylvania that has grown to include seven locations. He said a large part of what makes 3D Auto Body & Collision Centers successful is being a forward thinker and utilizing the latest technologies, such as the new equipment he purchased from Symach.

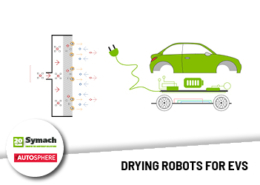

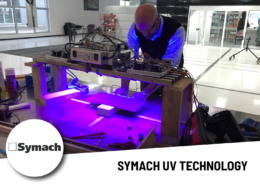

“In February of 2015, I was introduced to the Symach system and I knew instantaneously that was the future of the collision repair business and I had to be part of it!” said Niestroy, who operates in West Chester, Spring City, Oxford, Haverford, Wayne, Drexel Hill and their new location in Conshohocken where the Symach equipment was recently installed. “This technology gives us something that none of our competitors have—we can dry body filler, primer, sealer, waterborne base coat and clear coat in minutes not hours,” said Niestroy. “I know it sounds crazy, but we can paint vehicles in minutes with this technology.”

Prior to using this technology, he said it took up to three or more hours to complete the same process, which now takes just over an hour. “This technology works 100 times more efficiently than I could have ever imagined,” he said. The original plan was to purchase Symach equipment for their fifth location in Wayne, located on what is referred to as “the mainline.” “This is the premier location for any business,” said Niestroy. 3D also purchased two additional properties adjacent to the Wayne location, totaling nearly two acres. The intention was to demolish the existing building and construct a new, state-of-the-art collision repair mega center. After six months of meetings and working with architects and engineers, they couldn’t get the shop approved to be built in that location.

“After the setback with the Wayne project, I was still determined to make my dream a reality,” said Niestroy. “After scouring the area, and finding out where my insurance partners needed coverage, I located a building in Conshohocken, PA and our insurance partners all agreed this was the spot where they needed a partner,” said Niestroy. “The building was perfect. At 30,000 square feet, I knew I could build something so special and bigger than anyone else before me.” It took approximately six months to get the necessary approvals. “Over this course of time, my visions became clearer and clearer on how the building would be set up, how it would look, and how we would operate,” he said.

During the week-long visit, they also met the founder and inventor of the new technology, Osvaldo Bergaglio. “It became so clear to me that this is the future of the collision repair business and if I didn’t adapt to this system, 3D would be out of business,” he said. “Granted, it could be many years before that happened, but once the world of the collision repair business got hold of this technology, we would no longer have the competitive advantage.” “

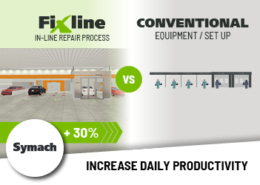

By using our custom-designed Symach solution, 3D Conshohocken can yield a 50 percent increase in touch time, a 25 to 30 percent reduction in labor cost and market disrupting cycle times with superior quality,” said Chad Seelye, Symach’s vice president USA.

Seelye said the new location in Conshohocken presented a few unique opportunities. For example, Symach installed the first SprayTron/ KombiTron solution in North America, which consists of one spray booth and one drying cabin that both utilize Symach’s DryTronic drying technology and robots. “When combined, it can produce average booth cycles of 30 minutes,” said Seeyle. “Using two painters and our unique Symach Application Process (SAP), a shop can produce 16 to 20 paint jobs of two to four plus panels per nine-hour shift.” As a comparison, he said to produce the same number of repairs in a conventional shop, it would take roughly four conventional paint booths and four painters. “This Symach solution requires 50 percent less production square footage and yields a 50 percent reduction in labor costs to produce the same number of units.” Symach also installed a FixStation solution. Seeyle said when combined with two combination technicians and the SAP, it can produce six to eight one-panel repairs per nine-hour shift. The FixStation is an all-in-one body repair/spray booth equipped with a FlyDry robot for curing paint and body filler, an in-ground lift and all power/air required to complete repairs,” said Seeyle. “The FixStation allows 3D to offer while-you-wait repairs, as the average one-panel repair only takes two hours.” In addition, the FixStation is oversized to accommodate taller commercial vehicles.

Although the Conshohocken location opened in January, Niestroy said they have been experimenting with the equipment for months. “This would not have been possible without the help of our partner paint company, PPG, and their tenacious efforts to perfect the paint formulas for this new paint drying process,” said. Niestroy said that some damaged vehicles can take up to a month or more to repair, while in other parts of the world vehicle repairs are completed in days and operate their facilities 24 hours a day 7 days a week to reduce cycle time and increase customer satisfaction. “As an industry, we need to provide a faster, more cost-effective repair while adhering to OEM standards,” said Niestroy. “My vision for repairing damaged vehicles is to do the repair in a few days rather than weeks and even do repairs while you wait.” He said most shops in the United States operate 8 a.m. to 5 p.m., only working five days a week. “I am guilty of this philosophy as well, but we are moving closer and closer to adopting the European philosophy—it just make sense,” said Niestroy. “Our customer and insurance partners demand a lot from us. Time is money to both the consumer and insurance companies.”

History of 3D Auto Body Niestroy began painting cars in his parents’ garage when he was 14 years old and quickly fell in love with auto body repairs. By the time, he graduated high school in 1981, he rented two 30’ x 60’ bays in a nearby building in West Chester. “I moved in, cleaned the building up and built a homemade paint booth and office,” he recalled. He visited several vehicle dealerships and asked if could repair one of their cars for no charge. After convincing two dealerships to provide him with vehicles, his business started to grow. he company purchased a downdraft paint booth in 1985. “At this time, nobody had a downdraft paintbooth so it gave 3D a huge competitive advantage,” said Niestroy. When he was 22 years old, Niestroy purchased the building from the landlord in 1990, the same year he purchased his first house, which he still lives in today, a few miles from the West Chester location. In 1997, he purchased his second location about a half an hour away. A third location was added in 2002 and his four and fifth locations were opened in 2006 and 2008, respectively. Over the past year, 3D opened two additional locations. In January, they hired their 101st team member. “I say ‘team member’ because we all work together to accomplish a common goal!”

Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl Symach srl

Symach srl

Symach srl

Symach srl

Symach srl

Symach srl