Paint Spray Booth Equipped with IR Drying Robot

PAINT BOOTH EQUIPPED WITH DRYTRONIC INFRARED DRYING ROBOT

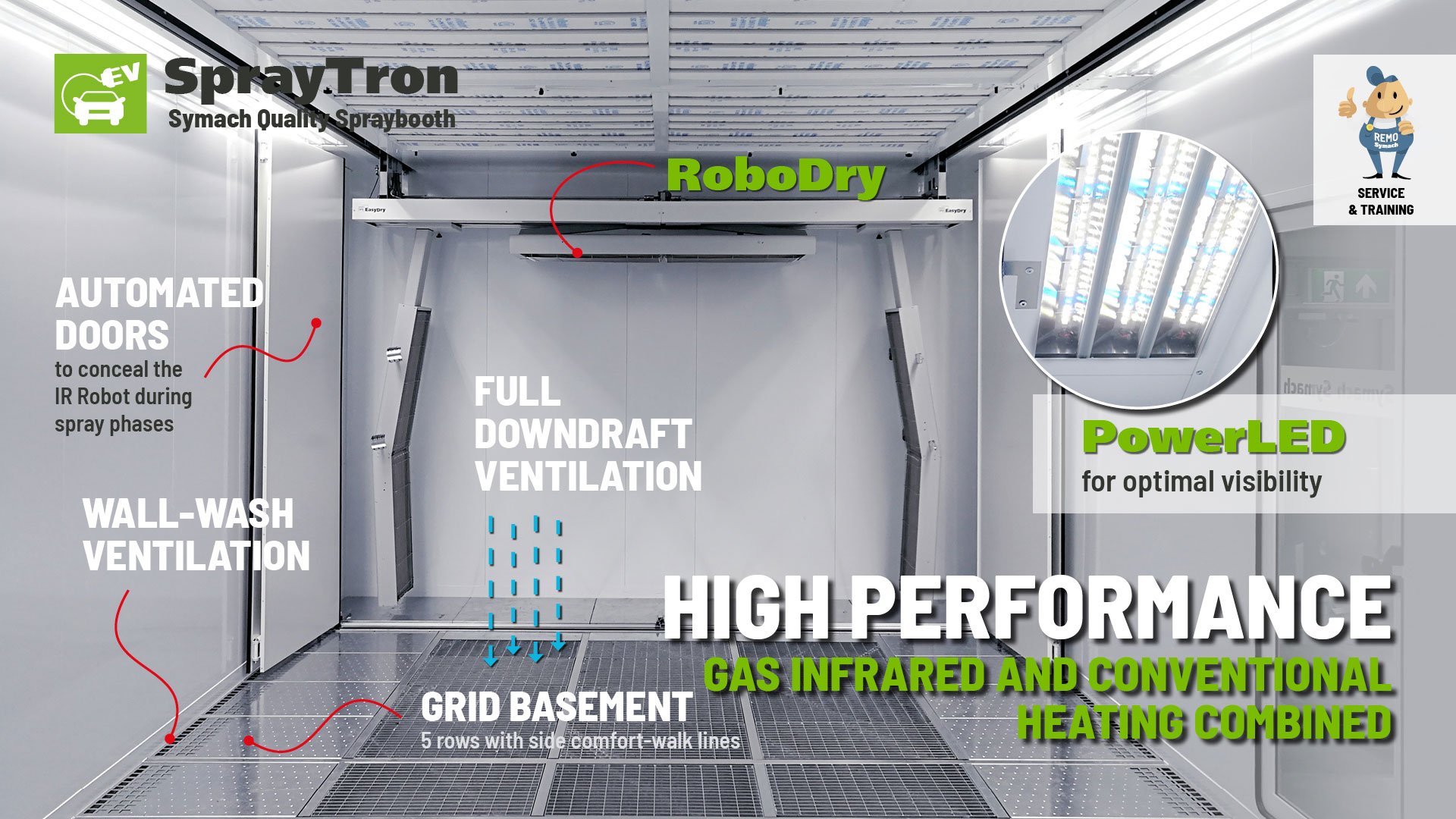

This cabin create a clean and safe environment for painting both passenger cars and commercial vehicles, as well as every part of the vehicle on stand. The dimensions of our SprayTron car paint booths can be customized to fit both standard sized cars, SUVs and commercial vehicles.

With a state-of-the-art ventilation system, including two curved fan blades, one for intake and one for air extraction, controlled by an inverter, you can have complete confidence in the exceptional air quality inside the cabin, thus protecting freshly coated surfaces from dust.

We also offer protective coatings and films for your cabin, ensuring their wear resistance and thus extending their service life and efficiency.

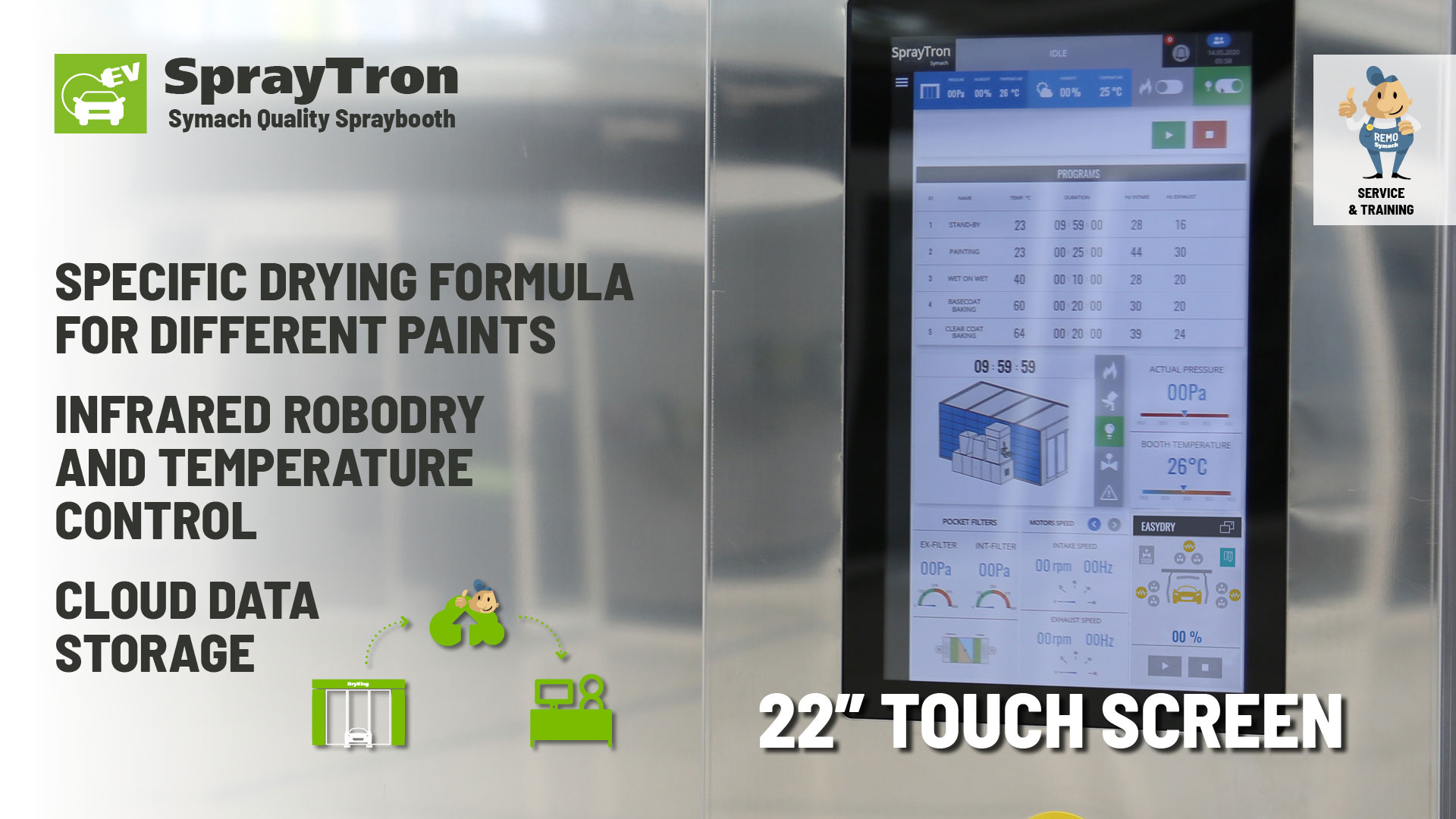

Unlimited drying formula included

- Spraying

- Drying wet on wet

- Dyring waterborne

- Drying many different clear and comfort climate to work inside the boot when no painting

- Clear baking with 80% recirculation

The electronic control system of the SprayTron automotive paint spray booth, is designed to identify and adapt to various operations within the booth automatically. It seamlessly adjusts the program, utilizing high-speed ventilation for the painting phases, moderate airspeed for drying (whether with a conventional burner or a robot), and minimal airspeed to ensure a comfortable climate during masking and cleaning phases. With this solution, painters are relieved from the need to manually operate any controls.

Each individual spraying and drying operation is meticulously recorded and securely stored in the cloud. Symach also offers REMO: a web-based platform for maintenance and training, which generates certifications for each cycle, including painting and drying times, as well as external humidity.

The SprayTron automotive paint spray booth can be configured with two pneumatic side doors. It is available in lengths of 8 meters (26.24 feet) or 9 meters (29.52 feet), and in heights of 2,7 meters (8.85 feet) or 3,2 meters (10.49 feet).

Infrared DryTronic Technology is Ready to be used to cure Electric Vehicles.

Symach’s patented Drytronic infrared drying technology is specifically designed to be EV-Ready. It focuses its energy directly on the painted surface, without raising interior or undercar/underhood temperatures. This ensures that no excessive heat is transferred to the electric batteries or the vehicle’s electronics, providing a safe and efficient drying process.

Furthermore, the energy-efficient nature of the Drytronic system contributes to reduced operating costs while promoting environmental sustainability.

Given these advantages, Drytronic technology is highly recommended for drying body filler and paint on electric vehicles, ensuring optimal results without compromising the vehicle’s sensitive components.

TECHNICAL FEATURES

Automotive Paint Spray Booth Dimensions

- Internal height: 3,00 m (9.8ft) or 3,50 m (11.5 ft),

- Inner width: 4,5 (14.7 ft) – can accommodate new SUVs, larger than conventional cars

- Inner length: 8,0 0m (26.2 ft)

Ventilation

- Ziehl Abegg’s fan with backward blades 34000 mc/h (20011 CFM) with a total static pressure of 500 Pa, controlled by inverter

- Pocket Filter protection to the G4 class fan with a filter area of 2,2 mq (21.5 sq ft)

Direct Flame Burner

Two power options available

EasyDry Drying Robot

- suitable for drying Electric Vehicles

Basement

- 5 lines of grids, including 2 comfort walking

PowerLED lights

- Light 5550 Kelvin

- 240,000 lumens

- 2000 – 2400 lux on the vertical side of the car

The 3 rows per side of Symach PowerLed lights represent an innovation in the head of lighting for painting booths, for 2 main reasons:

– The reflector is designed to send light to the vertical part of the car, while the lights are installed on the ceiling, so as not to interfere with any side pneumatic dampers. The result of lighting on the vertical part of the car is higher than that of 4 rows of T8 on the wall.

– The color of the light with the combination of blue color to alternating LEDs, offers 96% color fidelity and a white light very close to that of the sun. The blue color is also a relaxing effect for the human eye, which is not tired even after a day’s work.

User friendly touchscreen

- 15.6” Ultra HD (19 inches (9:16); PLC

Italian Design & Aesthetics

- 9 colors for external cover customization

- Doors in stainless steel

- CoverTop in ABS plastic mold injection