SPAP (Symach Paint Application Process) represents the proper painting method that integrates the use of both Drytronic technology and the robot.

Since it dries the paint in just a few seconds, the Drytronic technology enabled us to develop a painting process that significantly reduces flash-off times, as the robot performs the process even faster.

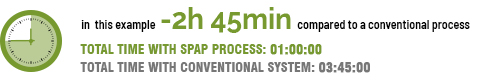

Drytronic drying quality is superior to any other drying process involving the use of hot air ovens or electric infrared heaters, because reticulation is instantaneous and 100% complete. The painting product is chemically stable and inert. This prevents the appearance of any future defects, while at the same time allowing for immediate sanding and polishing. The SAP application and drying process – is ideal for all painted products and for any brand name, even using different drying formulas, all while fully complying with the indications provided on the manufacturer’s technical data sheet. The time required to apply the paint to the products is reduced by 60% to 70%, while drying time is reduced by 80% to 90% with respect to any conventional system.

SPAP Process for Bodyfiller, Primer, Waterbase, Clear

Bodyfiller: this application and drying process allows for filling operations to be completed with a single application, offering superior compactness and quality with respect to the application of two coats using the traditional cycle, in less than half the time. For example, the continuous and uninterrupted filler application and drying takes place in less than five minutes.

Primer: The undercoat application process is carried out without interruption, because the flash-off between coats is performed by the robot. For example, the application and drying of three coats of Undercoat can be performed in less than eight minutes. Drytronic technology even allows for the Undercoat to be applied using a roller, in thicknesses and with application and drying times identical to that of spray applications, but with a 60% savings in paint product and a 100% savings in terms of masking times and materials.

Waterbase: Depending on the brand, the application of the two or three coats takes place consecutively and without interruption. For example, less than six minutes are required for application and drying of three painted panels.

Clear laquer: The application of two coats takes place consecutively and without interruption. For example, in order to paint three panels, less than twelve minutes are required for application and drying.

SPAP Process for DryTron

The DryTron dries every brand and type of paint in less than a minute and a half.

Bodyfiller dries in 40 seconds time

Primer dries in 40 seconds time

Waterbase dries in 50 seconds time

Clear coat dries in 80 seconds time

The time previously mentioned can change depending on the brand of paint and during the winter summer climates.

SPAP Process for Fixstation

The FixStation uses the FlyDry to dry paint.

Bodyfiller dries in 13 minutes

Primer dries in 11 minutes

Waterbase dries in 9 minutes

Clear laquer dries in 10 minutes