Symach Breaking News 01 | March 2021

Symach customer journey begins with the understanding of customer’s needs and objectives, in line with shop size and market segment. We are happy to share with you the real steps of this journey made by concept, projection, layout, production, installation, training, relationship, magic and stories

LATEST INSTALLATIONS

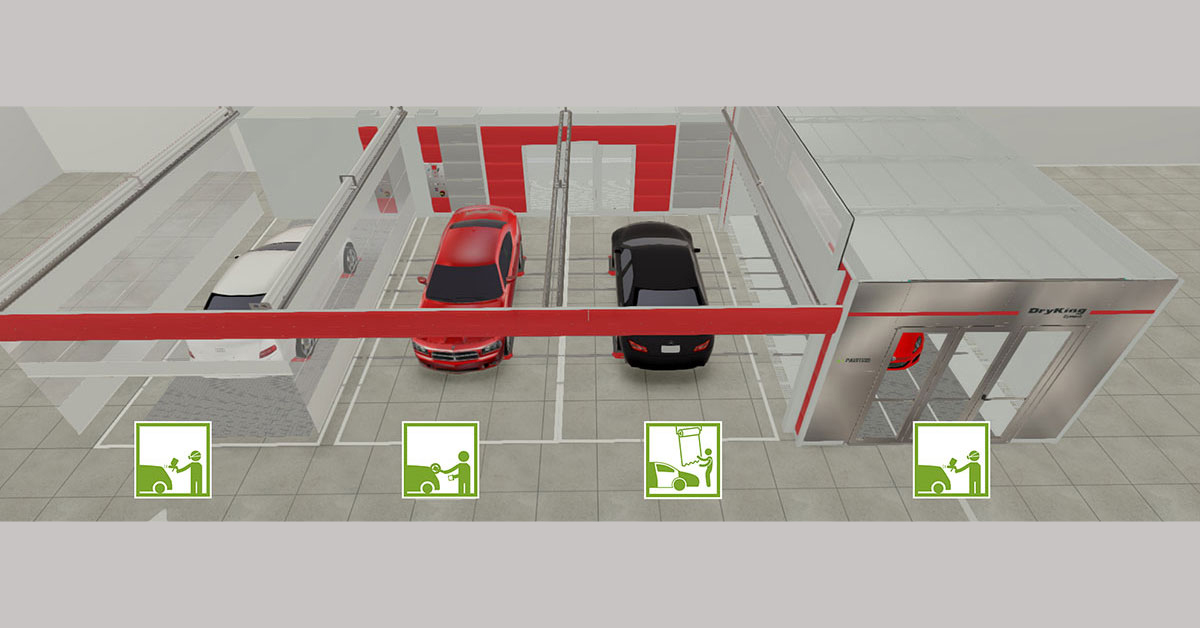

Crown Autobody & Glass, Mazda Group, Winnipeg, Canada

FixLine, for up to 8 job cycles per day

“The main advantages to utilizing Symach equipment include a greater focus on quality and restoring a vehicle to its original state as well greatly reducing the timeline to get a vehicle back on the road” said Ashok Dilawri, CEO of the Dilawri’s Crown Auto Group.

LATEST INSTALLATIONS

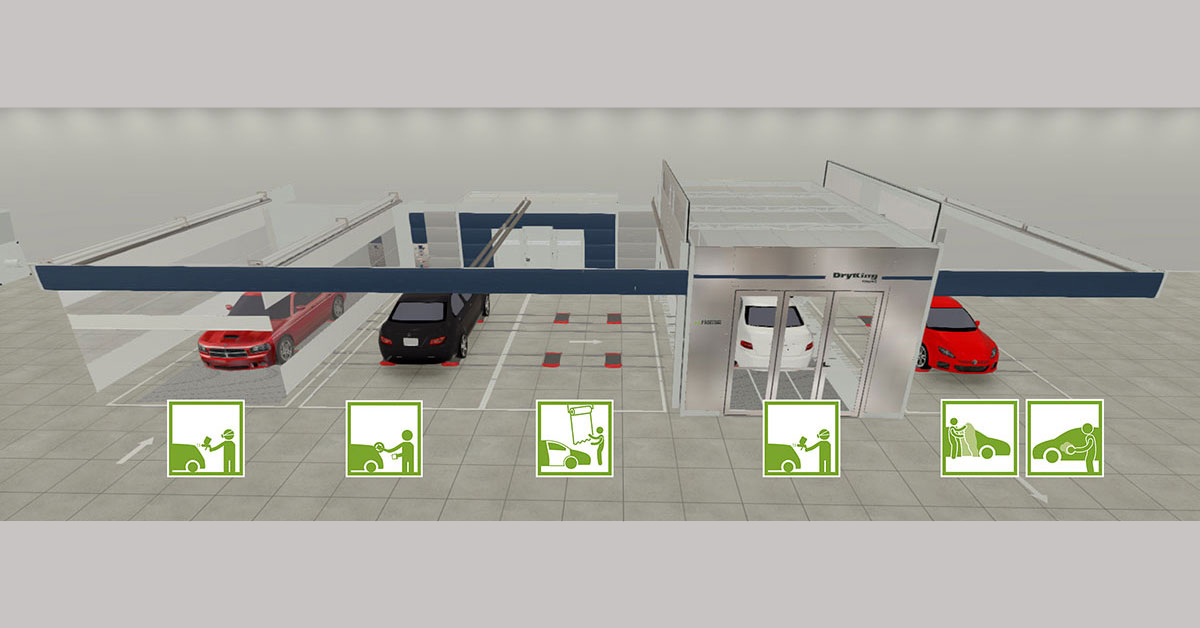

Garage Steveny, Ford dealership, Namur, Belgium

FixLine, for up to 20 job cycles per day

“A new bodyshop of 3’000 m2 will replace the current one, to be launched at the end of March”

LATEST INSTALLATIONS

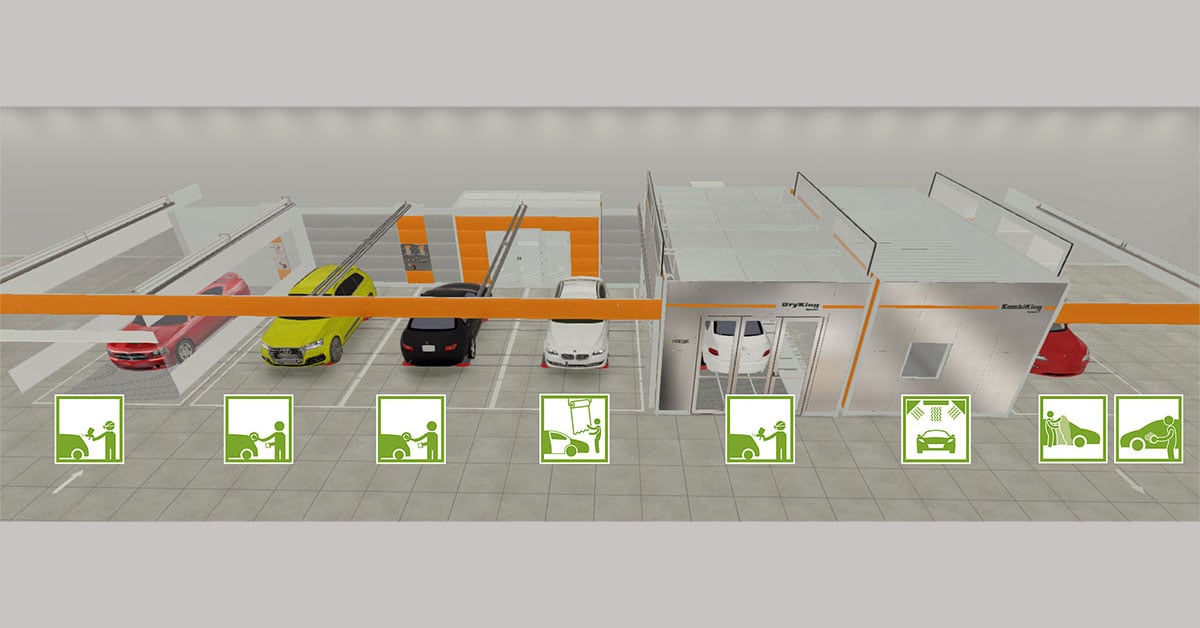

Priority 1, familly owned, multibrand dealership, Maryland, US

FixLine, for up to 16 job cycles per day

“Lou Cohen, CEO/President of Priority 1 Group asked: when were they going to paint the floors?” Jeremy Wojcik, General Manager, replied “They already did, look under the Symach PowerLED lights”. Lou replied “Wow, look at the difference, amazing! The quality of Symach PowerLED is stunning”.

LATEST INSTALLATIONS

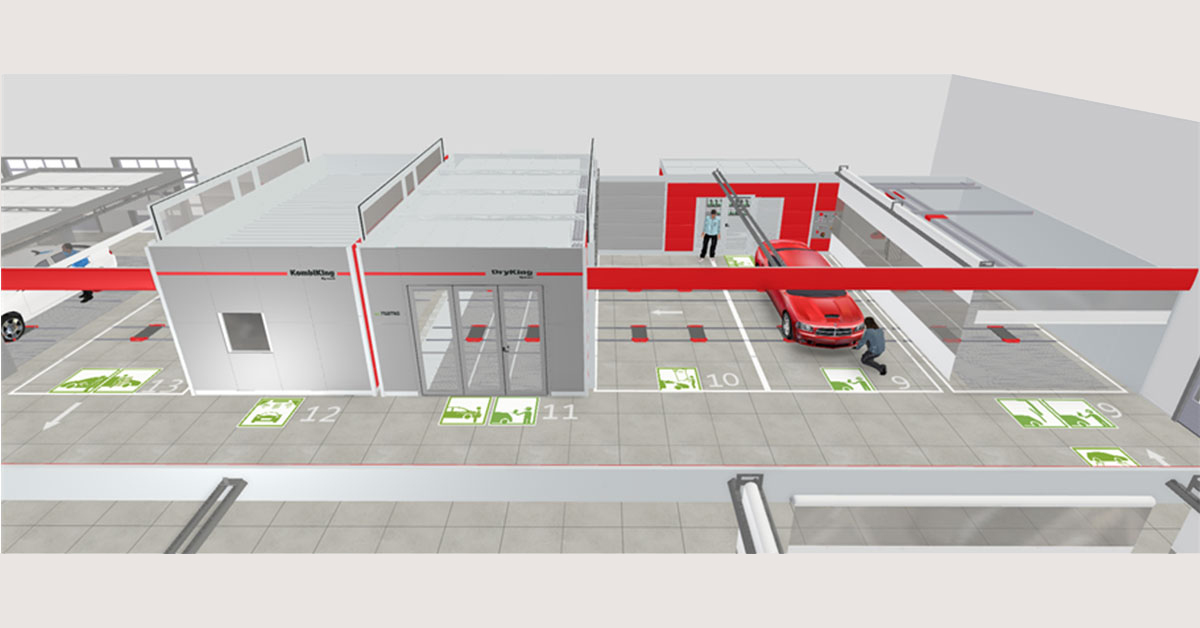

Specific Prestige, multi OEM brand approved bodyshop, Adelaide, Australia

DryKing, high performance booth

“the DryKing is fantastic whichever way you look at it: from its polished stainless entrance doors to the led lighting, or its colour combination outer coverings to its performance to achieve booth temperatures, with its ability to maintain temperature and produce clean work quickly”, said Jeff Williams, Owner of Specific Prestige

This edition’s video is featuring Mark Cunningham, based in Melbourne, Australia.

Listen to his 50 seconds video about the importance to establish company brand values and market segmentation when building a business plan.

SOLUTIONS

FixLine by Symach, the tailored solution that repairs from 5 to an unlimited number of job.

Its modular system allows to choose the number of bays and type of equipment to reach customer’s objectives. It includes the phases of primer application, sanding, masking, painting, drying, unmasking and polishing all in line, using the CarMover system to move the cars from one phase of the repair process to the next. All the equipment, from the spray booths and the drying booths, to the paint mixing room, the lights and all accessories, are designed and produced at Symach factory in Bologna, Italy.

PRODUCT NEWS

DryKing, is the new generation in spraybooths, it includes powerful burner and optimized air management for very rapid rise in temperature. With captivating line and design, aesthetic finishing and high quality components which ensure longevity and reliability.

PRODUCT NEWS

Portable UV-LED Lamp, with Symach UV-LEDtronic technology for drying and curing UV coating products.

The LEDs used are of different wavelengths all in the UV-A segment, these are assembled along a line of reflectors studied and designed to achieve the fastest and most efficient drying result on the market. The LEDs are controlled by an electronic board with a temperature control device that close the electric power in the event of the device overheating due to prolonged and continuous use of it. The LEDs are installed on an aluminium support equipped with a heat sink, allowing prolonged use of the lamp also for drying several car panels in sequence.

EFFICIENCY TOOLS FOR EVERYONE

Symach also designs and produces Accessories and Tools to help improve efficiency in body shop. Special Discount 10 % OFF for first order. Contact us or Shop Online

SYMACH IS PROUD TO PRESENT REMO

REMO is Symach training and maintenance platform developed in-house for its customers. It is a cloud-based technical platform, meant to support the daily work of collision repair technicians; to get familiar with Symach technology, for the periodic maintenance and to train new comers. The content is a rich library of written instructions and video tutorials about usage and maintenance of Symach equipment.

2 minutes video to find out tips and tricks about REMO usage and benefits

SYMACH WEBINAR SERIE “HOW TO DESIGN A NEW BODYSHOP”

Symach is leading the way in sharing best practices to bodyshop owners and site mangers to renovate their current shop or open a new one; regardless of the size of the shop. Based on a real example for a mid-sized shop planning to produce 10 job cycles per day, Osvaldo Bergaglio, CEO & Founder of Symach, explained bay by bay (stall by stall) the added value of installing Symach FixLine, the lean in-line repair process for bodyshops and car dealers. Read full News and Ask for webinar recording

FUTURE CENTER NEWS

Symach hosted Lechlerpaint technicians at its headquarters in Bologna, Italy, to test LECHLER new generation products to SYMACH equipment. The Hydrofan one-step additive using Symach met all the standards required.